Glass Bottle Filling Machine

500 to 24000BPH@330ml

PET Bottle Filling Machine

1000 to 40000BPH@500ml

Can Filling Machine

400 to 20000CPH@330ml

5 Gallon Water Filling Machine

100 to 1200BPH@3-5 Gallon

Manual Bottle Filling Machine

150 to 250BPH@330ml

Whole Water Bottle Filling and Packing Line

1. Automatic Washing

2. Automatic Filling

3. Automatic Capping

4. Water Treatment Plant

5. Removing cap machine

6. Inside&Outside Brushing Machine

7. Date and Batch Coding Machine

8. Sleeve Shrink Labeling Machine

9. PET Bottle Blowing System

10. Compressor Station

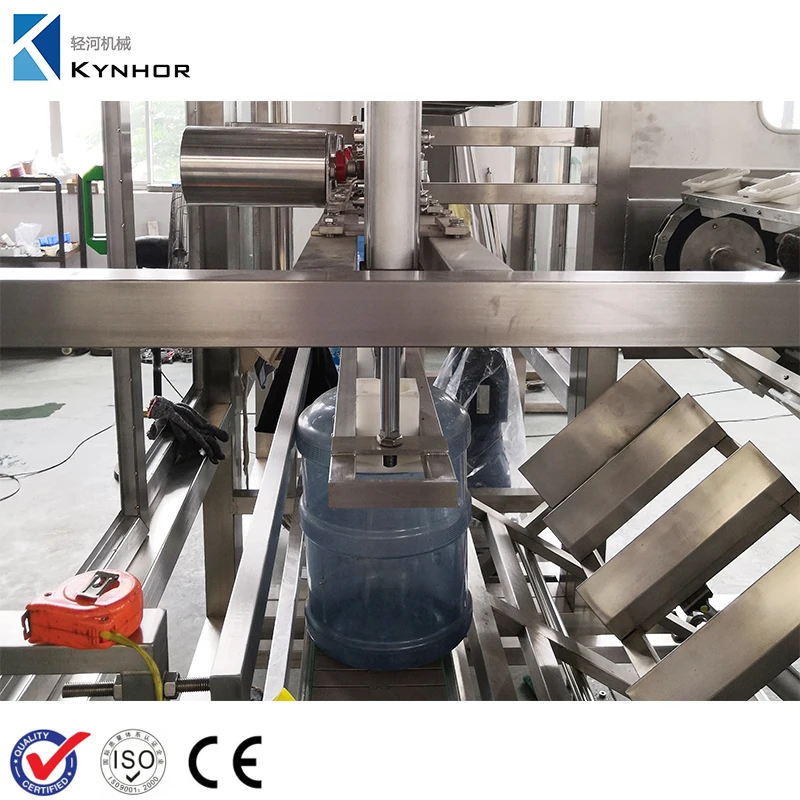

Kynhor 5 Gallon/18.9L Bottle Water Filling Machine

Kynhor 5 Gallon Water filling machine is designed for big bottle filling from 3 gallon to 5 gallon .

Cap removing machine

If your bottle is a recycling bottle and with a cap on it , this device can help you remove the cap from the bottle.

Outside&Inside brushing machine

Automatic barrel outer brushing machine specially work with 5 Gallon barreled water producing line. It is used for reducing the settling caused by the mineral water itself and some algae substances in the process of mineral water producing. The machine is made of excellent stainless steel with the advantage of easily-rinsing and corruption-resistance. The main electrical elements adopt the products with brands of SIEMENS and OMRON. Pneumatic elements adopt the products with brand of AIRTAC.

Main Machine Features.

1. Shape structure adopted concave and convex shape,

perfect appearance also reduces the leakage.

2. The thickness of the stainless steel plate which used for 600bph is 3mm.

3. Tank and the heating pipe in tank are removable which become more clean sanitation.

Filling Part Features.

1. Uploading and dropping barrels changed from 45 degree to translatory which is more stable.

2. Nozzle can insert into 10-15cm of the barrel in order to rinse little impurities down. Rinsing pump is separately controlled by different magnetic valves. Pump only work when there is barrel on that. It can avoid the mixture of different cleaning fluid.

Capping Parts.

1. Liquid level difference is controlled in 1cm.

2. Machine is equipped with Cap Sterilization system, which is 1.2m. The system make products more clean and safe by using sterilization and finished water.

3. Customers can choose to equip ABB/SEW motor, GRUNDFOS water pump, FESTO pneumatic component.

Automatic convey belt

The chain board on conveyor is made with stainless steel. The appearance of foot stand is perfect, and the height can be adjusted.

Water treatment system.

1. Raw water tank + Raw water pump

2. Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3. Reverse Osmosis (one level)

4. UV sterilizer

5. Finished water tank + Pure water pump

PET Bottle Blow Molding Machine

1. The unique cam linking system integrates mold-opening,mold-locking and bottom mold-elevating in one movement,equipped with high speed servo driving system which greatly shortens the blowing cycle and accelerates the speed.

2. Minimized transfer pitch for increasing heating efficiency and saving energy.

3. Easy to adjust,exchange and access heating oven;Protection for preform thread against heating.

4. Through finite element analysis to optimize modular design for reducing machine wearing and moving inertia.

5. Efficient consumption: Up to 45 % less electricity and 35 % less compressed air

Labeling machine.

This machine adopts international advance technology; Sleeve the label on the Glass or PET bottle,And then shrink on the position which bottle body designated.

This machine's structure is compact,and suitanble for the production line of different direction and different height.

Bottle Packaging Machine.

It adopts the photoelectric sensor to detect online, gather signals which are controlled by PLC, and adopts piston as executable element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished product.

Shanghai Kynhor Machinery Co., Ltd.

1. Standardized workshop of total 8,000 square meters.

2. The equipment will be tested and run for more than 12 hours before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechnical stability.

3. 2 Years Warranty and 2 Years Spare parts for free .

4. Go through Alibaba.com to ensure the timely delivery and the safety of your funds .

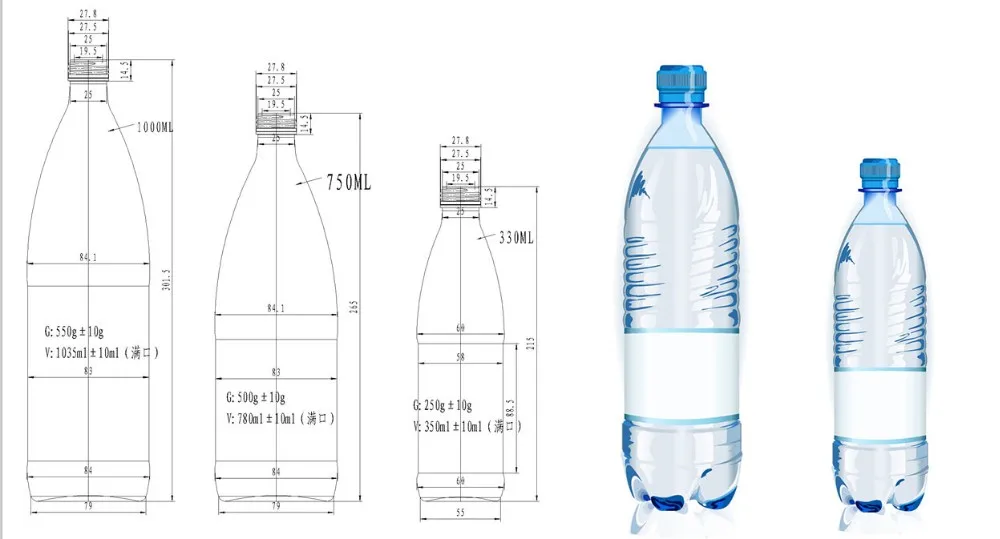

Bottle Design Drawing

Whole Production Line Layout Design Drawing

Turn Key Project

7*24 Hours Service

Q.1.ARE YOU A MANUFACTURER OR TRADING COMPANY?

● Kynhor is a manufacturer with trading company who is registered in the Chinese Business Administration and has the right to operate and sell it legally.

● Kynhor cooperates with Alibaba who will supply you a lot of service to protect you .

● Kynhor has a professional engineer team who all have more than 25 years experience in beverage filling machine manufacturing .

Q.2.HOW TO VISIT OUR FACTORY?

● If you are interested in our products, you may visit our factory at any time , we can pick you up from the station or the airport near our city .

● Seeing is believing , you can see our machine quality after your visit .

Q.3.HOW TO ENSURE THE MACHINE QUALITY?

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Before shipping, the whole machine will run more than 12 hours to ensure the stable running in your factory

Q.4.HOW TO GUARANTEE YOUR FUNDS?

● We go through Alibaba.com Guarantee Service, which can protect your funds to be safe.

● We will send you pictures of the machine every week to ensure the delivery.

Q.5.KYNHOR MACHINE AFTER-SALE SERVICE

● We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

● When you finish the preparation conditions,our fast and professional after service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

● We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

● We provide 2 year warranty with spare parts free and life-long technical support .

Kynhor-Help Each Customer Make Professional Decision !

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.