APV Plate Heat Exchanger

- Heat Transfer Area

- 0.1 m² – 3,000+ m²

- Design Pressure

- Up to 2.5 MPa (25 bar); high-pressure models available up to 4.0 MPa (40 bar)

- Design Temperature

- –25°C to +200°C

- Port Connection Size

- DN15 (½") to DN500 (20")

Other recommendations for your business

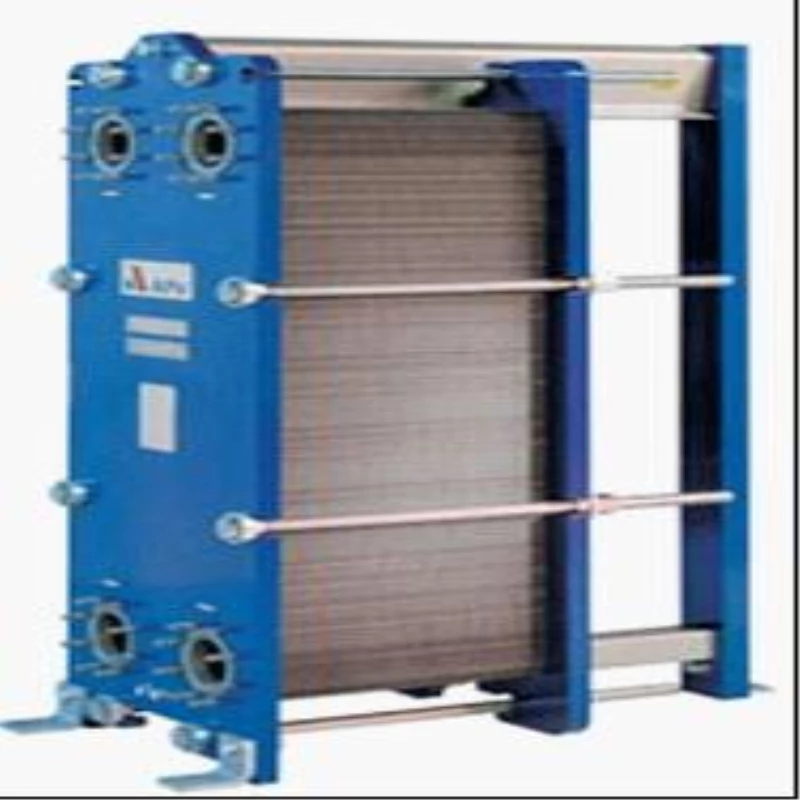

Principle of APV heat exchanger:

The working principle of plate heat exchanger is that two liquids flow on one side of a thin corrugated metal plate, and heat is easily transferred between the two liquids. Compared with other heat exchange equipment, plate heat exchangers occupy less space and are lighter.

2. Technical advantages of APV plate heat exchanger

APV plate heat exchanger is the inventor of plate heat exchangers in the world. APV plate heat exchanger research has been at the forefront of the world for a long time. In addition to researching and developing fluid flow and heat transfer efficiency, APV pays more attention to the convenient operation and maintenance of plate heat exchangers, the longevity of plate gaskets and other aspects.

High efficiency

1) High heat transfer coefficient, which can save investment costs by reducing the required heat transfer area. 2) Low liquid retention, saving start-up time and reducing operating costs. 3) Up to 97% heat recovery. 4) Compared with shell and tube heat exchangers, it meets the heat exchange requirements of end difference equal to 1°C.

Easy maintenance

1) No complex maintenance is required, such as X-ray, ultrasonic and other non-destructive detection methods. 2) No moving parts minimize vibration, ensure reliable operation and reduce maintenance costs. 3) Compared with shell and tube heat exchangers, it occupies a small area and is easy to repair and maintain.

Cost

1) Due to the high heat transfer efficiency of the plate type and the low material consumption, the investment cost is lower than that of the shell and tube heat exchanger. 2) The plate heat exchanger uses less cooling water, so the cost of supporting pipes, pumps and valves is also greatly reduced compared with the shell and tube heat exchanger. 3) The installation cost is low compared with the shell and tube heat exchanger. 4) The low fouling coefficient improves thermal efficiency and minimizes operation and maintenance costs. 5) The lower flow rate optimizes the service life of the plate and reduces the need for maintenance.

Advantages of APV plate heat exchangers in heat exchange applications:

High heat exchange efficiency: save equipment investment and supporting costs, low installation costs;

Save cooling water: low operating costs;

Small end difference: meet harsh heat exchange requirements;

Reliable operation: safe and stable operation;

Easy maintenance: simple, convenient and low cost

III. Characteristics of plates and gaskets of APV plate heat exchangers

Design selection: After the flow rate is determined, according to the requirements of temperature difference and pressure drop, when selecting the APV plate heat exchanger, by adjusting the angle of the plate corrugation and the aspect ratio of the plate, the fluid mechanics and thermodynamics are optimized to make the APV plate heat exchanger more efficient, more reliable to use and more economical to invest.

Advantages of APV gasketed plate heat exchangers:

♦ High heat conversion / 3-5 times higher membrane heat transfer coefficient

♦ Heat recovery or reproduction efficiency up to 95%

♦ Small liquid resistance, so the heat exchange reaction time is fast;

♦ Fluids flow in opposite directions in their respective channels of parallel channels

Economical and compact structure

♦ Equipment footprint can be reduced by 90%, weight reduction, and performance improvement;

♦ Reduced fluid resistance reduces the required overflow volume, also reduces the cost of expensive maintenance fluids, and speeds up thermal reaction time;

♦ Reduced capital costs and installation expenses;

♦ High energy recovery rate and reduced energy consumption;

Easy to clean

♦ High heat conversion efficiency, reducing dirt caused by debris and dust;

Easy to clean and easy to replace plates;

♦ Use high-efficiency CIP to remove dirt, or replace chemical membranes;

Easy to maintain

♦ Easy to inspect, maintain and clean both sides of the heat transfer surface;

♦ Easy to maintain at any time in the equipment installation part;

Flexibility

♦ Modular design is adopted to facilitate future equipment expansion and improvement;

♦ Multi-function and multi-liquid flow design is adopted in a single device;

♦ Easy to modify according to new requirements;

♦ A wide variety of sizes and styles are available to facilitate the selection of the best equipment;

IV. Application of APV plate heat exchanger

Conventional thermal power plantsAuxiliary cooling of many thermal power plants requires the use of plate heat exchangers

●Most applications are to remove the heat generated by friction from the auxiliary system

●The main demand is liquid-liquid heat exchangers, i.e. water-water, ethylene glycol-water, and oil-water

●The design pressure in the auxiliary system is rarely higher than 1.0 MPa

●Typical application design temperatures are usually between 49℃ and 100℃

●Central cooling

●Vacuum pump cooling

●Generator cooling

●Feedwater pump lubricating oil cooling

●Closed-circuit water cooling

●Turbine lubricating oil cooling

●Drainage cooling (heat recovery)

●Cooling of jacket and valve water

●Cooling of stuffing box sealing oil

●Sealing pipe oil cooling

●Air conditioning compressor cooling

● Emergency diesel engine cooling

Hydropower station

● Turbine lubricating oil cooling

● Cooler of liquid bottom control system

Nuclear power station

● Non-nuclear area

- Same as conventional thermal power plant

● Nuclear area - Nuclear area reactor, etc.

- Moderator cooler

- Fuel cell cooling and purification system

- Shell and condenser pool cooling

- Core emergency cooling

- Waste treatment system

- Neutron shield cooling

- Accident standby cooling

● Turbine lubricating oil cooling

● Cooler of liquid bottom control system

V. APV heat exchanger series

APV heat exchanger series: single-wall gasket seal (Paraflow), double-wall (Duo-Safety), half-welded plate, ParaBrazed plate heat exchanger, Hybrid heat exchanger, plate evaporator, scraped surface heat exchanger, tube heat exchanger

Model series of APV heat exchanger:

A series: A095, A085, A055, A145, etc.

Q series: Q030 (thin), Q030 (thick), Q055, Q080, etc.

N series: N25/N35, N40, N50, etc.

H series: H7, H12, H17, etc.

K series: K34, K55, etc.

J series: J060, J092, J107, J185, J107, etc.

B series: B063, B110, B134, B158, B205, etc.

SR series: SR1, SR9, SR6 GH, SR14, etc.

T series: T4, etc.

R series: R50-R, R50-L, etc.

The working principle of plate heat exchanger is that two liquids flow on one side of a thin corrugated metal plate, and heat is easily transferred between the two liquids. Compared with other heat exchange equipment, plate heat exchangers occupy less space and are lighter.

2. Technical advantages of APV plate heat exchanger

APV plate heat exchanger is the inventor of plate heat exchangers in the world. APV plate heat exchanger research has been at the forefront of the world for a long time. In addition to researching and developing fluid flow and heat transfer efficiency, APV pays more attention to the convenient operation and maintenance of plate heat exchangers, the longevity of plate gaskets and other aspects.

High efficiency

1) High heat transfer coefficient, which can save investment costs by reducing the required heat transfer area. 2) Low liquid retention, saving start-up time and reducing operating costs. 3) Up to 97% heat recovery. 4) Compared with shell and tube heat exchangers, it meets the heat exchange requirements of end difference equal to 1°C.

Easy maintenance

1) No complex maintenance is required, such as X-ray, ultrasonic and other non-destructive detection methods. 2) No moving parts minimize vibration, ensure reliable operation and reduce maintenance costs. 3) Compared with shell and tube heat exchangers, it occupies a small area and is easy to repair and maintain.

Cost

1) Due to the high heat transfer efficiency of the plate type and the low material consumption, the investment cost is lower than that of the shell and tube heat exchanger. 2) The plate heat exchanger uses less cooling water, so the cost of supporting pipes, pumps and valves is also greatly reduced compared with the shell and tube heat exchanger. 3) The installation cost is low compared with the shell and tube heat exchanger. 4) The low fouling coefficient improves thermal efficiency and minimizes operation and maintenance costs. 5) The lower flow rate optimizes the service life of the plate and reduces the need for maintenance.

Advantages of APV plate heat exchangers in heat exchange applications:

High heat exchange efficiency: save equipment investment and supporting costs, low installation costs;

Save cooling water: low operating costs;

Small end difference: meet harsh heat exchange requirements;

Reliable operation: safe and stable operation;

Easy maintenance: simple, convenient and low cost

III. Characteristics of plates and gaskets of APV plate heat exchangers

Design selection: After the flow rate is determined, according to the requirements of temperature difference and pressure drop, when selecting the APV plate heat exchanger, by adjusting the angle of the plate corrugation and the aspect ratio of the plate, the fluid mechanics and thermodynamics are optimized to make the APV plate heat exchanger more efficient, more reliable to use and more economical to invest.

Advantages of APV gasketed plate heat exchangers:

♦ High heat conversion / 3-5 times higher membrane heat transfer coefficient

♦ Heat recovery or reproduction efficiency up to 95%

♦ Small liquid resistance, so the heat exchange reaction time is fast;

♦ Fluids flow in opposite directions in their respective channels of parallel channels

Economical and compact structure

♦ Equipment footprint can be reduced by 90%, weight reduction, and performance improvement;

♦ Reduced fluid resistance reduces the required overflow volume, also reduces the cost of expensive maintenance fluids, and speeds up thermal reaction time;

♦ Reduced capital costs and installation expenses;

♦ High energy recovery rate and reduced energy consumption;

Easy to clean

♦ High heat conversion efficiency, reducing dirt caused by debris and dust;

Easy to clean and easy to replace plates;

♦ Use high-efficiency CIP to remove dirt, or replace chemical membranes;

Easy to maintain

♦ Easy to inspect, maintain and clean both sides of the heat transfer surface;

♦ Easy to maintain at any time in the equipment installation part;

Flexibility

♦ Modular design is adopted to facilitate future equipment expansion and improvement;

♦ Multi-function and multi-liquid flow design is adopted in a single device;

♦ Easy to modify according to new requirements;

♦ A wide variety of sizes and styles are available to facilitate the selection of the best equipment;

IV. Application of APV plate heat exchanger

Conventional thermal power plantsAuxiliary cooling of many thermal power plants requires the use of plate heat exchangers

●Most applications are to remove the heat generated by friction from the auxiliary system

●The main demand is liquid-liquid heat exchangers, i.e. water-water, ethylene glycol-water, and oil-water

●The design pressure in the auxiliary system is rarely higher than 1.0 MPa

●Typical application design temperatures are usually between 49℃ and 100℃

●Central cooling

●Vacuum pump cooling

●Generator cooling

●Feedwater pump lubricating oil cooling

●Closed-circuit water cooling

●Turbine lubricating oil cooling

●Drainage cooling (heat recovery)

●Cooling of jacket and valve water

●Cooling of stuffing box sealing oil

●Sealing pipe oil cooling

●Air conditioning compressor cooling

● Emergency diesel engine cooling

Hydropower station

● Turbine lubricating oil cooling

● Cooler of liquid bottom control system

Nuclear power station

● Non-nuclear area

- Same as conventional thermal power plant

● Nuclear area - Nuclear area reactor, etc.

- Moderator cooler

- Fuel cell cooling and purification system

- Shell and condenser pool cooling

- Core emergency cooling

- Waste treatment system

- Neutron shield cooling

- Accident standby cooling

● Turbine lubricating oil cooling

● Cooler of liquid bottom control system

V. APV heat exchanger series

APV heat exchanger series: single-wall gasket seal (Paraflow), double-wall (Duo-Safety), half-welded plate, ParaBrazed plate heat exchanger, Hybrid heat exchanger, plate evaporator, scraped surface heat exchanger, tube heat exchanger

Model series of APV heat exchanger:

A series: A095, A085, A055, A145, etc.

Q series: Q030 (thin), Q030 (thick), Q055, Q080, etc.

N series: N25/N35, N40, N50, etc.

H series: H7, H12, H17, etc.

K series: K34, K55, etc.

J series: J060, J092, J107, J185, J107, etc.

B series: B063, B110, B134, B158, B205, etc.

SR series: SR1, SR9, SR6 GH, SR14, etc.

T series: T4, etc.

R series: R50-R, R50-L, etc.

M series: M92, etc.

Supplier's popular products

Contact Supplier

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.