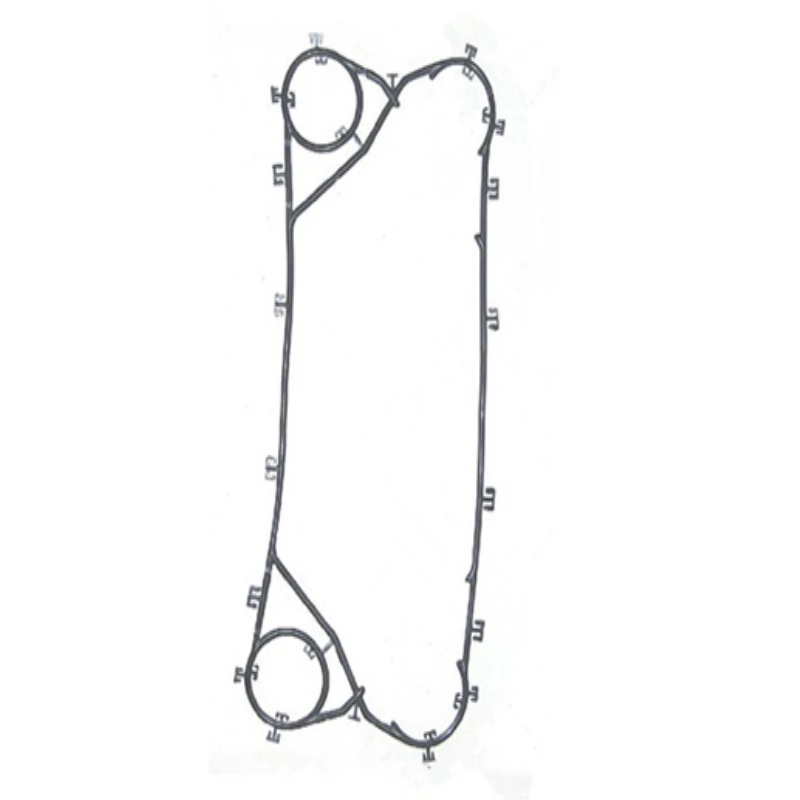

Alfa Laval Plate Heat Exchanger Gasket Plate

- Plate Material

- AISI 304 / 316L stainless steel

- Gasket Material

- EPDM (Ethylene Propylene)

- Compatibility & Identification

- Model series (e.g., M10-MFG

- Operating Conditions

- T10-BFM)

Other recommendations for your business

Alfa Laval, a Swedish company, was established in 1883. Alfa Laval plate heat exchanger has a complete range of product models, and its unique metal plate design provides high thermal efficiency with the smallest heat exchange area; In addition, there are many contact points evenly distributed in a mesh between the plates, making them very sturdy and sturdy. These all mean that compared to most other suppliers, Alfa Laval can provide you with thinner and more efficient metal sheets. The sealing gasket materials of Alfa Laval include NBR (nitrile rubber), HNBR (hydrogenated nitrile rubber), EPDM (ethylene propylene diene monomer rubber), Viton (fluororubber), and the plates are made of stainless steel (Alloy 304, Alloy 316, etc.), titanium and titanium palladium (Ti, Ti Pd), 20Cr, 18Ni, 6Mo (254SMO), nickel (Ni), HASTELLOY alloy (C276, D205, B2G), graphite, and other materials. The Alfa Laval heat exchanger product series includes detachable plate heat exchangers, semi welded plate heat exchangers, brazed plate heat exchangers, fusion welded plate heat exchangers, and fully welded plate heat exchangers. The model series of plate heat exchangers are A series: A3, A10B, A15, A15BW, AK20, AM10, etc.; M series: M3, M6M, M10B, M10M, M20M, MX25B, M30-FM, etc.; T series: T20-MFG, T20B, TS6, TS20M, etc. Alfa can choose the most suitable form and material according to customer needs.

Supplier's popular products

Contact Supplier

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.