Use of Molybdenum

Molybdenum plays a leading role in the iron and steel industry, accounting for about 80% of the total molybdenum consumption.

This was followed by chemicals, which accounted for about 10 percent. Molybdenum is also used in electrical and electronic technology, medicine and agriculture, accounting for about 10% of total consumption.

Alloy domain

The largest consumption of molybdenum is in the steel sector, where it is used in the production of alloy steel (approximately 43% of molybdenum in total steel consumption), stainless steel (approximately 23%), tool steel and high speed steel (approximately 8%), cast iron and rolls (approximately 6%). Most of the molybdenum is directly used in steel or cast iron after industrial molybdenum oxide pressing block, a small part is first melted into ferro molybdenum, and then used in steel. Molybdenum as an alloy element of steel has the following advantages: improve the strength and toughness of steel; Improve the corrosion resistance of steel in acid-base solution and liquid metal; Improve the wear resistance of steel; Improve hardenability, weldability and heat resistance of steel.

Chemical industry

Lubricant: molybdenum dioxide is a good solid lubricant, because of its low friction coefficient, high yield strength, can be used normally in vacuum and various ultra-low temperature, high temperature, so it is widely used in gas turbine, gear, mold, aerospace, nuclear industry and other fields.

Electronic and electrical field

Molybdenum has good electrical conductivity and high temperature resistance, and its thermal expansion coefficient is similar to that of glass. It is widely used in manufacturing core wire, lead wire and hook parts of spiral filament. In addition, molybdenum wire is also an ideal electrode wire for electric discharge cutting machine tools, which can cut various kinds of steel and hard alloy. Its discharge processing is stable, and can effectively improve the accuracy of die.

Medical field

Molybdenum is one of the essential trace elements of human body, and is also a component of a variety of enzymes. Its main function in the body is to participate in the interaction between sulfur, iron and copper. Appropriate amount of molybdenum can promote human development, enhance oxygen storage in the body, inhibit tumor, maintain myocardial energy metabolism, and protect myocardial muscle. However, lack of molybdenum can lead to caries, kidney stones, Keshan disease, Kashin-bacco-disease, esophageal cancer and other diseases. Therefore, molybdenum is also used in medicine, such as ammonium molybdate, which is mainly used in patients with long-term dependence on intravenous high nutrition.

Animal husbandry field

The biological effects of molybdenum are mainly achieved by indirectly affecting the biological activities of some molybdenum-containing enzymes in animals. In addition, molybdenum plays a special role in nutrient metabolism of ruminants. On the one hand, molybdenum, as a component of nitrate oxidase in ruminant microorganisms, directly participates in the transformation of feed nitrate in the rumen; on the other hand, molybdenum, as a cofactor of sulfate oxidase, has a stimulating effect on rumen microorganisms. This helps the ruminant to digest the coarse fibers, which in turn promotes the growth of the ruminant.

Agricultural field

Molybdenum is one of the essential "trace elements" in plant body, lack of molybdenum will affect the normal growth of plants. As a necessary trace element for plant growth, molybdenum can not only promote the absorption of phosphorus by plants, but also accelerate the formation and transformation of alcohols in plants, improve the content of chlorophyll and vitamin C in plants, and improve the resistance to drought, cold and disease.

| item | Hot sale best price TZM seamless molybdenum alloy tube polished molybdenum tube pipe |

| Place of Origin | China |

| Brand Name | Shaanxi Zhuohangxin Metal Materials Co. LTD |

| Model Number | molybdenum tube pipe |

| Dimensions | customized |

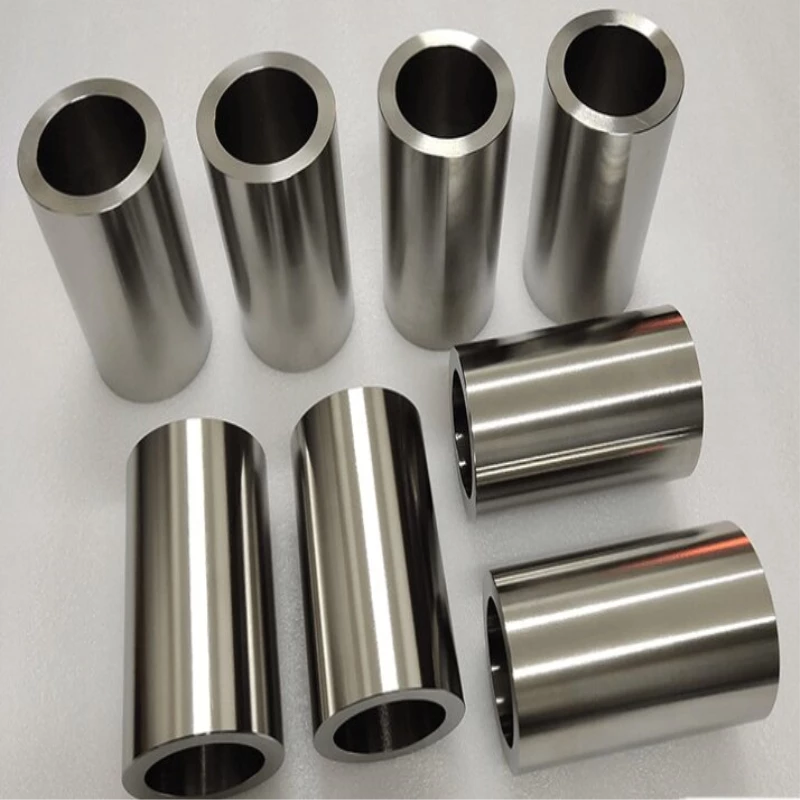

| Product name | TZM seamless molybdenum alloy tube polished molybdenum tube pipe |

| Application | Heating Element, vacuum furnace, vacuum |

| Shape | tube pipe barrel hollow bar |

| Surface | polished, black, machined, welded |

| Purity | 99.95% min, TZM |

| Material | molybdenum, TZM |

| Density | 10.2g/cm3 |

| Technique | seamless, welded |

| Melting piont | 2623dc |

| Size | AS AGREEMENT |

Molybdenum tube

Diameter (mm)

Wall thickness (mm)

Length (mm)

Forged Molybdenum tube

30-50

2-10

<1000

Forged Molybdenum tube

50-150

3-15

Sintered Molybdenum tube

150-200

5-20

Sintered Molybdenum tube

200-300

8-20

Sintered Molybdenum tube

300-400

8-30

Molybdenum tubes can be used as protective sleeves for tungsten-rhenium thermocouples, grids and cathode support tubes for high-power electron tubes, sputtering targets, etc.

Molybdenum tube material: high purity molybdenum/high temperature molybdenum.

Molybdenum tube classification: sintered molybdenum tube, forged molybdenum tube.

Molybdenum tube uses: thermocouple protection tubes, heat insulation tubes, sintered tubes, protective sleeves, etc.

Molybdenum Advantages:

Hot sale best price TZM seamless molybdenum alloy tube polished molybdenum tube pipe

•1, Good corrosion resistance (The surface of molybdenum tube is easy to produce a layer of dense natural protective film, It can be well to protect the matrix from corrosion by artificial anodized oxidation and coloring, good casting performance can be cast aluminum alloy or processing Plastic deformation of good aluminum alloy.)

•2, High strength (molybdenum tube have the high strength.After a certain degree of cold processing can strengthen the matrix strength, some grades of molybdenum tube can also be enhanced by heat treatment)

•3, Good thermal conductivity (The conductive thermal conductivity of molybdenum only less than the silver, copper and gold)

•4, Easy processing (After add some certain alloying elements, you can get a good casting performance of aluminum alloy casting or processing plastic deformation of aluminum alloy)

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.