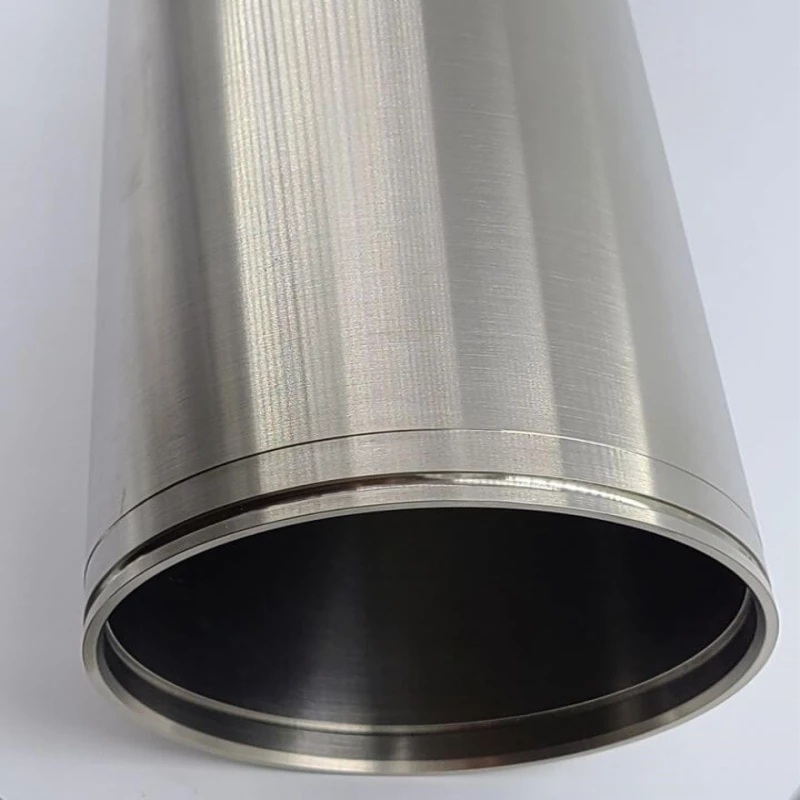

Tantalum Tube Target is a target material made of Tantalum Tube as raw material. The following is a detailed introduction to Tantalum Tube Target:

FeaturesHigh melting point: The melting point of tantalum is as high as 3017℃, which makes the Tantalum Tube target still maintain stable physical and chemical properties in high temperature environment, and it is not easy to melt or deform. It can be used in some processes that need to withstand high temperature.

Strong corrosion resistance: Tantalum has excellent corrosion resistance. At room temperature, Tantalum has strong corrosion resistance to strong acids such as hydrochloric acid and concentrated nitric acid, as well as highly corrosive mixed acids such as aqua regia. Therefore, when the tantalum tube target is used in various harsh chemical environments, its performance will not be significantly affected, and its service life is long.

High density: The density of tantalum is about 16.65g/cm³. The high density makes the tantalum tube target have good stability and impact resistance during use, and it is not easy to be displaced or damaged due to external factors.

Good electrical conductivity and thermal conductivity: Tantalum has good electrical conductivity and thermal conductivity, which makes the tantalum tube target play an important role in some applications that require electrical or thermal conductivity, such as electron beam evaporation coating processes.

Preparation process

Raw material selection: Generally, tantalum metal with higher purity is selected as raw material, and common purity levels are 99.9%, 99.95%, etc., to ensure the performance and quality of tantalum tube targets.

Smelting and processing: Tantalum metal is melted and purified by vacuum arc melting, electron beam melting and other methods, and then processed by forging, rolling, drawing and other processing techniques to make tantalum tubes. During the processing, the process parameters need to be strictly controlled to ensure the dimensional accuracy and surface quality of the tantalum tube.

Cutting and processing: The prepared tantalum tube is cut into appropriate lengths according to actual needs, and further processed, such as turning, grinding, etc., to meet the requirements of tantalum tube target size and shape in different application scenarios.

Cleaning and packaging: Finally, the processed tantalum tube target is cleaned to remove oil and impurities on the surface, and then packaged by vacuum packaging or inert gas protection packaging to prevent the tantalum tube target from being contaminated or oxidized during storage and transportation.

Application fields

Semiconductor industry: In the process of semiconductor chip manufacturing, tantalum tube targets are often used in physical vapor deposition (PVD) process. Tantalum thin film is deposited on the semiconductor substrate by sputtering coating to form a barrier layer, which is used to protect the copper interconnect structure, prevent the diffusion of copper atoms, and improve the performance and reliability of the chip.

Optical coating field: Tantalum tube targets can be used for coating optical elements such as optical lenses, filters, and anti-reflection films. By sputtering tantalum atoms to form a uniform tantalum film on the surface of the optical element, the reflectivity, transmittance and other properties of the optical element can be improved, and the optical performance and stability of the optical element can be improved.

Decoration industry: Tantalum formed by sputtering tantalum tube targets The film has a metallic luster and good chemical stability, and can be used for decorative coating. For example, coating a tantalum film on the surface of watch casings, jewelry, crafts, etc. can not only improve its decorative effect, but also increase its wear resistance and corrosion resistance.

Flat panel display industry: In the manufacturing process of flat panel displays, tantalum tube targets can be used to deposit tantalum films as electrode materials, barrier layers or protective layers, etc., which helps to improve the performance and life of the display.

Other fields: Tantalum tube targets can also be used in glass coating industries such as magnetic storage media, inkjet printer heads, automotive glass and architectural glass, as well as optical communications, etc., to improve the performance of materials or achieve specific functions

Products Description

| Product Name | Purity | Density | Surface Condition | Thermal Treatment |

| Ta Planar Target | 3N5 | 16.65g/cm3 | Ground | Annealing |

| Ta Rotary Target | 3N5 | 16.65g/cm3 | Ground | Annealing |

| Parameters | Typical Value |

| Composition | Ta |

| Purity | ≥99.99% |

| Boiling point | 5731k (5458 ° C) |

| Melting point | 3290k (3017 ° C) |

| Size | customized |

| Electrical resistivity | <2×10-4 Ω·cm |

| Dimension(mm) | |||

| Maximal OD | Maximal Length | Maximal single segment length | Bonding ratio |

| 145-150 | 3000 | 250 | ≥95% |

Application

1.Metallizing, Electron-beam Spraying ,sinteting annealing in reducing atmosphere in electronics.

2. Military and light industries

3.Evaporate small lengths of wire or to evaporate materials.

3.Tantalum boat is ideal for use in small evaporation systems.

4.Tantalum boats sources are used for the vacuum evaporation of materials.

Application

Tantalum is widely used in aviation and aerospace industry, high temperature technology, atomic energy industry and chemical industry thanks to its high melting point, corrosion resistance and good cold working performance.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.