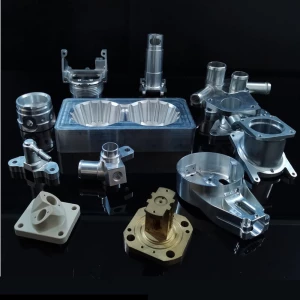

5 Axis CNC Machining Services for high precision and complex parts or prototypes

What is 5 Axis Machining?

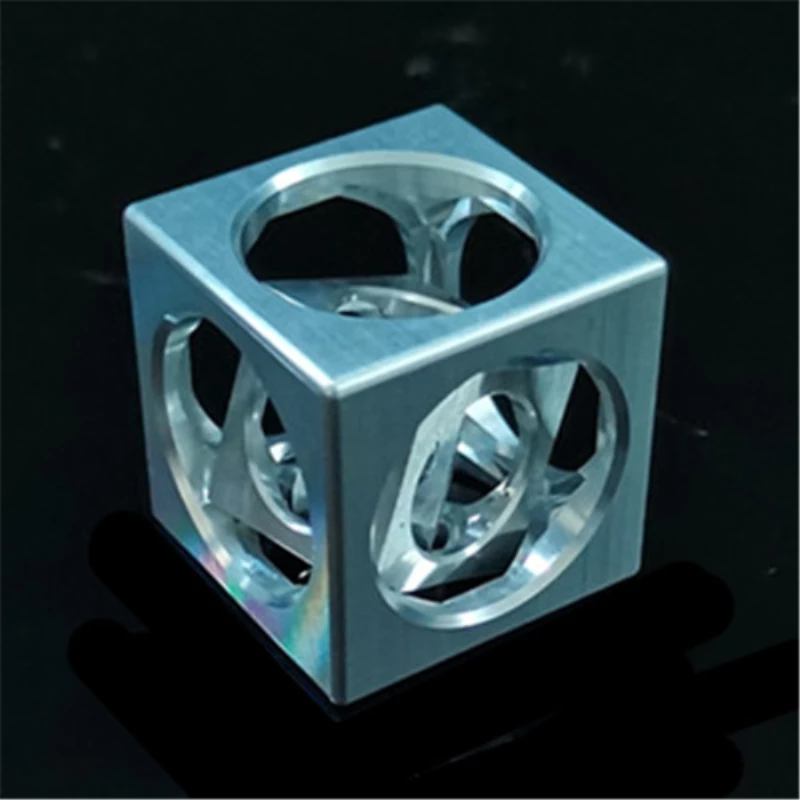

The 3, 4, or 5 axis machining is defined related to the number of directions in which the cutting tool can move, this also determines the ability of a CNC machine to move a workpiece and a tool. 3-axis machining centers can move a component in X and Y directions and the tool moves up and down along Z-axis, while on the 5 axis machining center, the tool can move across the X, Y and Z linear axes as well as rotates on the A and B axes, which makes the cutter can approach the workpiece from any direction and any angle. 5 axis machining is different from 5-sided machining. Therefore, 5 axis CNC machining services allow infinite possibilities of the machined parts. Hook surface machining, unusual shape machining, hollow machining, punching, oblique cutting, and more special processes can be done with 5 axis CNC service.

Why Choose 5 Axis CNC Machining Services

5 axis CNC service at Brightstar has strong capabilities to deliver precision machining products based on the demands and custom design given by clients, to reach or exceed your expectation.

5 Axis machining center has many benefits over a traditional center:

- 5 axis machining is well-adapted with good flexibility, it can cut tool accessories and shell parts with extremely complex contours and high precision dimensions;

- It can cut chips on multiple sides of a part simultaneously in one setup, which reduces fixture and setup preparation, saves a lot of time

- High precision, stable quality, CNC devices pulse is 0.001mm, precision could be achieved 0.003mm, Excellent surface finishes can be achieved, improves the overall quality of 5 axis CNC parts

- High production automation reduced the labor intensity of operator and benefit for PA management system.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.