316L SS Double-Ended Sample Cylinder, 1/4 in. FNPT, 500 cm3, 3000 psig (207 bar)

316L SS Double-Ended Sample Cylinder, 1/4 in. FNPT, 500cm3, 3000 psig (207 bar)

Sizes from 10 to 3785 cm³ (1 gal)

Working pressures up to 5000 psig (344 bar)

304L and 316L stainless steel and alloy 400

Wanan Sample Cylinder is widely used on petroleum device, chemical device and so on, especially leak-proof sampling for toxic, harmful, flammable, explosive and some other dangerous gas or liquid with medium or low pressure, like residual oil hydrotreating unit, heavy oil catalytic cracking unit, gas fractionation unit and so on. Sample collected by Wanan sample cylinder is authentic, accurate, no residual liquid, no residual gas emissions, protecting operators from harmful media, meanwhile no harm to environment, and eliminating accident from flammable, explosive median during sampling.

♥ Body made of seamless tubing provides consistent wall thickness, size, and capacity.

♥ Smooth internal neck transition allows easy cleaning and eliminates trapped fluids.

♥ Cold-formed female NPT threads provide greater strength.

♥ Heavy-wall end connections provide strength and resist flaring.

♥ Full-penetration gas tungsten arc-weld construction provides leak-tight sample containment.

♥ Sizes from 40 to 3785 cm3 (1 gal)

♥ Working pressures up to 5000 psig (344 bar)

♥ 304, 316L stainless steel resists intergranular corrosion.

♥ 304L and 316L stainless steel double-ended cylinders are available with dual certification to DOT and TC requirements.

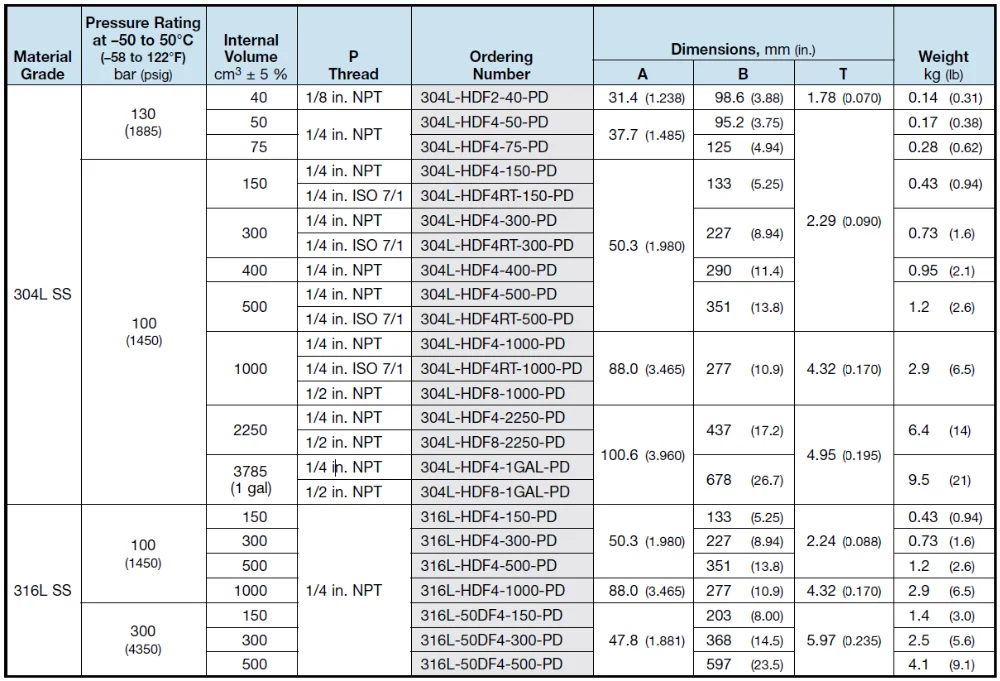

Dimensions, in millimeters (inches), are for reference only and are subject to change.

1) Rupture Disc Units

Compressed gas cylinders are equipped with pressure relief devices. Rupture disc units protect sample cylinders from overpressurization by venting the cylinder contents to atmosphere. The rupture disc is welded to a body that is threaded into a valve body or a rupture disc tee and sealed by an elastomer O-ring. The rupture disc can be easily replaced without removing the valve or the tee from the cylinder.

Materials of Construction

2) Nonrotating-Stem Needle Valves with Rupture Disc Units

Ordering Information and Dimensions

3) Rupture Disc Tees

Ordering Information and Dimensions

1) Caps and Plugs

Caps and plugs protect Swagelok tube fitting or NPT end connections on valves during cylinder transport. Contact your authorized Swagelok representative for details.

2) Carrying Handle

This accessory provides a convenient way to carry sample cylinders. The handle is made from 304 stainless steel and is available for use on 300 cm3 and larger cylinders.

3) Outage Tubes

Features

♥ Made from 316 stainless steel or alloy 400 tubing

♥ Offered in 1/4 or 1/2 in. NPT sizes

♥ Marked “Outage Tube” for identification

Construction

Outage tubes are welded to the male inlet end of an adapter or tee. This adapter or tee is then threaded into the female port of a sample cylinder.

Outage tubes can also be welded directly to the male inlet of a Swagelok nonrotating stem needle valve. The valve is then threaded into the female port of a sample cylinder.

Tube Length

Outage tube length (L) is measured from the end of the pipe fitting to the end of the tube. Standard tube length is 10.4 in. (26.4 cm). Tubing can be cut to a desired length; instructions are included.

Purpose

Outage tubes provide a vapor space of the desired volume in cylinders containing liquefied gases, so that liquid in the cylinder can expand if the temperature increases. Without enough vapor space, a small temperature increase can cause the liquid to expand and increase the pressure dramatically.

See local regulations and other appropriate guidelines for safe filling limits for your application.

Use

Outage is the vapor space in the cylinder expressed as a percentage of the total volume of the cylinder.

% outage = (vapor space/total volume) 3 100

The cylinder is held vertically with the outage tube at the top, as shown. The length of the outage tube determines the amount of vapor space. Sampling methods and the use of the outage tube are described in technical publications such as ASTM D1265, Standard Practice for Sampling Liquefied Petroleum (LP) Gases (Manual Method).

1) PTFE Coating

Internal cylinder surfaces can be coated with PTFE to provide a nonstick surface, which aids in cleaning. To order, add -T to the cylinder ordering number.

Example: 304L-HDF4-300-T

2) Electropolishing

Electropolishing provides a clean internal surface with a high degree of passivation. To order, add -EP to the cylinder ordering number.

Example: 304L-HDF4-300-EP

3) Additional Marking

Cylinders can be laser etched to meet specific identification requirements, such as company name, address, serial number, or order number. Swagelok will not mark cylinders with the intended contents.

Laser Etching—To order, add -LE to the cylinder ordering number, followed by the specific information.

Example: 304L-HDF4-300-LE Company Name and Address

This information will be laser etched on the cylinder wall.

Cylinders with the above options conform to DOT specifications.

Please make a safe product selection. When selecting products, the total system design must be considered to ensure safe, trouble-free performance, founction, material compatibility, adequate ratings, proper installation, operation and maintenance are the responsibilities of the system designer and user.

From quote to delivery, detail support can be offered.

1.CAD drawing

2.P&ID

3.Component selection

4.Bill of material

5.Professional services such as bending and welding

6.Testing to guarantee the system

7.Professional packaging and delivery

1. What is the acceptable MOQ?

For this miniature sample cylinder , our acceptable MOQ is 1pc. Any trial order in small quantity is welcome.

2. What is the Delivery time?

For samples,we usually have them in stock, so the delivery time will be quite short .

For normal order, the delivery time should be in 2 weeks.

3.What is the acceptable payment term?

T/T, Paypal ,Western Union, MoneyGram, L/C, D/A, D/P

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.