3 In 1 unit mineral water machine malaysia/ water bottling plant manufacturers

3 In 1 unit mineral water machine malaysia/ water bottling plant manufacturers

Full automatic bottle blowing machine--Air conveyor--Washing filling capping 3in1 machine--Light checker--Blow dryer--Dater printer--Lableing machine --Packing machine -Stock

The machine is mainly applied for the filling of water. Integrating with washing, filling and sealing, it realizes full automation in the whole process, suitable for plastic bottle and glass bottle filling of mineral water and purified water.

Advantages

1. Automatic 3 in 1 Water Bottling Machine adopt Rinsing / Filling / Capping 3-in-1 technology, PLC control, Touch Screen, it is mainly made of SUS304.

2. It is used for filling kinds of non-carbonated water, such as still water, drinking water. mineral water, spring water, flavored water.

3. Its usual production capacity is in 2000-20,000bph, 0.3-2L PET bottle is available.

4. Pivotal electrical part use Mitsubishi, OMRON, SIEMENS.

5. Filling accuracy is more or less than 1%.

6. We can provide water treatment machine, bottle blowing machine, bottle filling machine, dater printer, labeling machine,wrapping machine etc.

Technical Data

| Model | Washing heads | Filling heads | Capping heads | Capacity(B/H) | Motor power(KW) | Overall dimension(MM) |

| CGF8-8-3 | 8 | 8 | 3 | 2000-2500 | 1.2 | 2000*1400*2300 |

| CGF14-12-5 | 14 | 12 | 5 | 2000-4000 | 1.5 | 2100*1400*2500 |

| CGF16-16-5 | 16 | 16 | 5 | 5000-7000 | 2 | 2250*1600*2600 |

| CGF18-18-6 | 18 | 18 | 6 | 6000-8000 | 2.2 | 2460*1720*2650 |

| CGF24-24-8 | 24 | 24 | 8 | 8000-12000 | 3 | 3100*2100*2650 |

| CGF32-32-10 | 32 | 32 | 10 | 12000-15000 | 4 | 3500*2500*2650 |

| CGF40-40-10 | 10 | 40 | 10 | 16000-20000 | 7.5 | 4600*1800*2650 |

| CGF48-48-12 | 48 | 48 | 12 | 20000-24000 | 9.5 | 5200*4500*3400 |

1).Automatic Washing-Filling-Capping 3-in-1 Machine

1. We use direct connection technology between air conveyor and in-feeding starwheel to substitute in-feeding screw and conveyor to ease the process of bottle-size-changing.

2. Neck-hanging technology is applied in bottle transportation. Instead of traditional starwheel, we use neck-hanging gripper to make bottle-size-changing easily, without equipment height adjustment, only arch board and starwheel such little nylon parts need to be changed.

3. Specially-designed rinser grippers which are made of stainless steel are firm and endurable, with no contact to screw part of the bottle to prevent second pollution.

4. Rapid gravity filling valve with high flow makes filling faster with accurate liquid level and without any liquid loss.

5. Splint of starwheel using twist descending way to simplify the process of bottle-size-changing.

6. The machine applies to the production of natural mineral water, purified water and mineralized water.

The Reverse Osmosis process uses a semi-permeable membrane to separate and remove dissolved solids, organics, pyrogens, submicron collodial matter, viruses, and bacteria from water. The process is called "Reverse" Osmosis since it requires pressure to force pure water across a membrane, leaving the impurities behind. Reverse Osmosis is capable of removing 95 - 99% of the total dissolved solids (TDS) and 99% of all bacteria, thus providing safe, pure water

1.The Blow Molding system does not require highly trained operators to produce consistent quality bottles.

2.The bottle making process starts by loading preforms into the preheater.

3.The preheater uses a variable speed track that moves the preforms through a heating tunnel. The heat tunnel has specially designed heating elements for a consistent heating operation with minimal maintenance.

4.When the preforms have made one "trip" through the preheater, they are manually loaded two(three or four) at a time into the blow molder. .

5.After the bottles are formed in the blowing cycle, they are removed and the cycle continues. The finished bottles are then loaded directly onto a conveyor for filling or can be stored for later use.

It comprises of shrink sleeve applicator, shrink tunnel, steam generator and conveyor and can be incorporated into customer's existing production line or operated stand-alone.

Filled or empty containers are transported via an infeed conveyor and then metered via a rotating feedscrew, As the containers enter the labeler, the labels in web form are opened and formed into a tube by a mandrel, fed in precise registration with a printed graphic, cut in precise registration, applied to a container which is then transported via conveyor to a steam tunnel where controlled steam heat shrinks the sleeve tightly onto the container.

Our products are sold well not only in domestic, but also in Chile,Venezuela,Egypt,Peru,Maldives,United States,Brunei Darussalam,Saudi Arabia,Panama,Cambodia,Bhutan,Bolivia,Bulgaria,Nicaragua,Dominican Republic,Kenya,Somalia,Australia,Switzerland,Mozambique and other countries.

| If you want to know more about our transaction history. Pls click | VIEW MORE > |

Q1.Are you a factory or trading company?

A1.We are a professional water treatment and filling equipment manufacturing factory that set up for 16 years.We always pay attention to the development of the industry !.We can give a discount according to the quantity of machine you purchase.

B1.At the same time,we take effective measures to control the production process for ensuring the quality of products.

Our products are certified.And we can supply SGS, BV, TUV, ISO9001, ISO14001, OHSAS18001, CE certification.

C1,Website: http://www.jmangel.com Website on alibaba: http://jmangel.en.alibaba.com

Q2.Where is your factory located? How can I visit there?

A2:Our factory is located in No.141-143 plant, Qingnian Road, Chaolian Town, Pengjiang District, Jiangmen, Guangdong, China, All our clients, from home or abroad, are warmly welcome to visit us!

Q3.What products does your company offer by yourself?

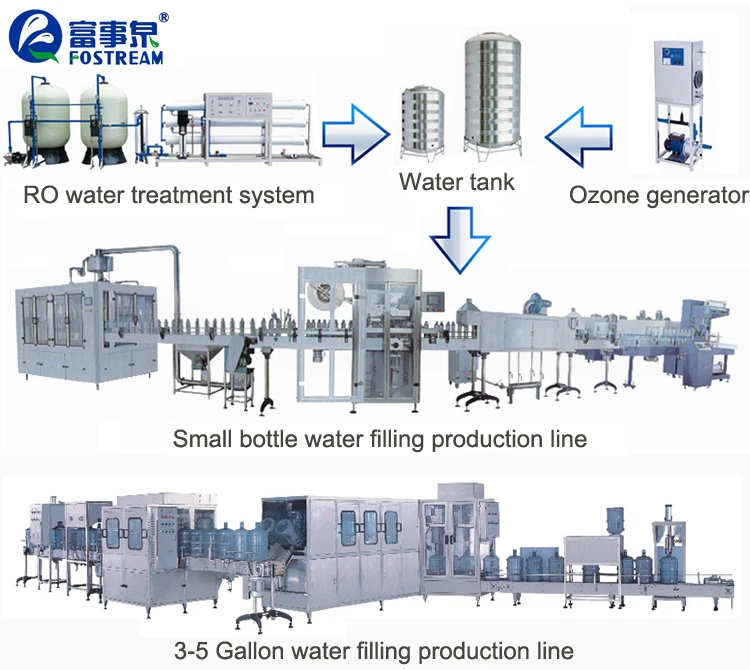

A3:We are specialized in RO water treatment machines,UF water treatment machines,small bottle filling machines and 5 gallon filling machines etc.

Q4: How can I know your machine works well?

A4: Before delivery, we shall test the machine working condition for you.

Q5: Do you have technical support after we purchased your machines?

A5: We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems.

| Related Products | ||

| ||

| Barrel Water Filling Machine Production Solution | ||

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.