Product Feature

The 0.18mm Molybdenum Cutting Wire for Line Separator Lcd Front Glass Iphone can also be used to repair worn mechanical parts, such as bearings, crankshafts, etc. On the other hand, it also can be used as an intermediate transition coating. Because of its good abrasion resistance, it can be an indispensable material for metal thermal spraying technology. It is widely used in the surface thermal spraying of automotive parts such as piston rings, synchronizing rings, and transmissions.

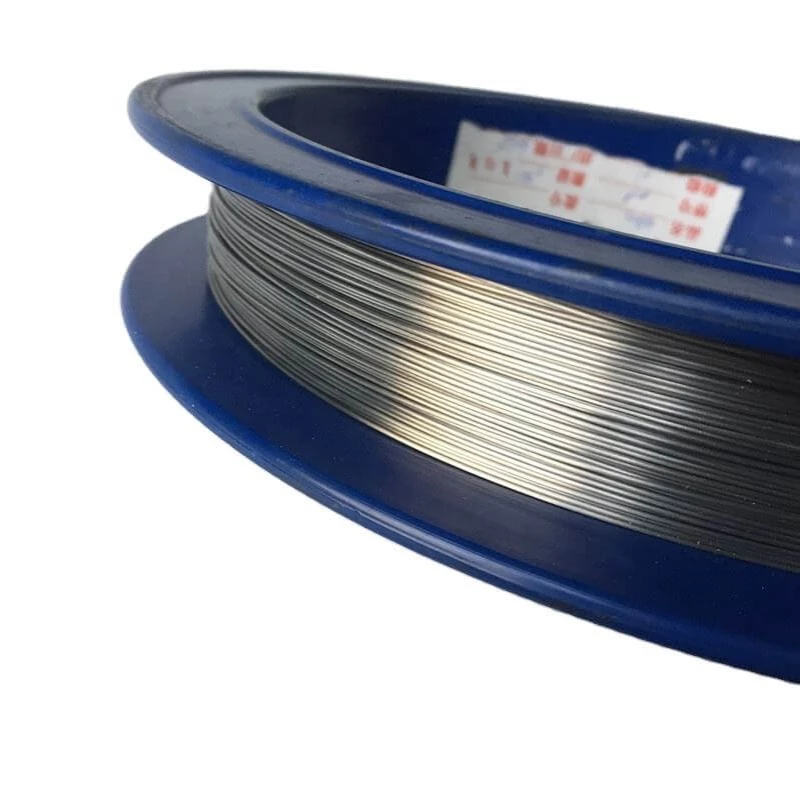

Product Description

The 0.18mm Molybdenum Cutting Wire for Line Separator Lcd Front Glass Iphone is a kind of molybdenum wire with high interlayer peel strength. In addition, the high-performance electrode wire in wire cutting can be an organic combination. There are two kinds of grade options, thus to provide more choices to meet need and it ensures longer service life for use. Under high temperature and heavy load conditions, the coating has high interlayer peel strength.

| Product Name | Black molybdenum wire for high temp furnace |

| diameter range | dia0.18-3.0mm |

| Unit weight | 1.15kg, 2.3kg, 5kg, 10kg or according to customers' requests |

| Grade | Mo1, MLa, TZM, MoY |

| Surface | black or alkali washing |

| Main Features | good quality, high purity: ≥99.95%, long service life |

| Application | Suitable for making filament,supporting wire and lead-out,etc. , in electronic and lighting industry, also widely used in EDMprocessing , used as heating elements, spraying molybdenum wires, etc. |

Molybdenum wire application:

1.Molybdenum wire(spray moly wire)is mainly used for auto parts spraying,such as piston ring,synchronizer rings,shift elements,etc.Molybdenum spray wire is also used in repairs of machine parts,such as bearing,bearing shells,shafts,etc.

2.Molybdenum wire for wire-cutting application is characteristic in high tensile strength,good electric discharge,smooth finish,high cutting speed,long life and etc.

3.It is also used as electric light source parts,high temperature and heating elements,etc.

Molybdenum wire advantage:

1.Molybdenum wire high pricision,line diameter tolerance control at less than 0 to 0.002mm

2.The ratio of breaking wire low,processing rate is high,good performance and good price.

3.Can finish the stable long time continuous processing.

Molybdenum is one of the silver-white refractory metals. Due to the very strong bonding force between atoms, it has high hardness, and molybdenum is stable in air or water at room temperature or elevated temperature. Molybdenum has the characteristics of small expansion coefficient, good electrical conductivity, and good thermal performance. At room temperature, it does not react with hydrochloric acid, hydrofluoric acid and alkali solutions, and is only soluble in nitric acid and aqua regia or sulfuric acid. Therefore, molybdenum and its alloys have good application prospects and have been used in metallurgy, agriculture, electrical, chemical, environmental protection and aerospace and other important sectors, becoming one of the important raw materials and irreplaceable strategic materials in the national economy.

When molybdenum is heated in the air, the color changes from white to dark gray; when the temperature reaches 520°C, molybdenum will be slowly oxidized to form MoO3. When the temperature reaches above 600°C, molybdenum is rapidly oxidized to MoO3. When molybdenum is heated to 700~800°C in water vapor, it will start to generate MoO2. If the heating continues, MoO2 will be oxidized to MoO3.

We have more categories for you. lf you can't find the products you want above,just fill in the form and tell us whatproducts you want to import from China.