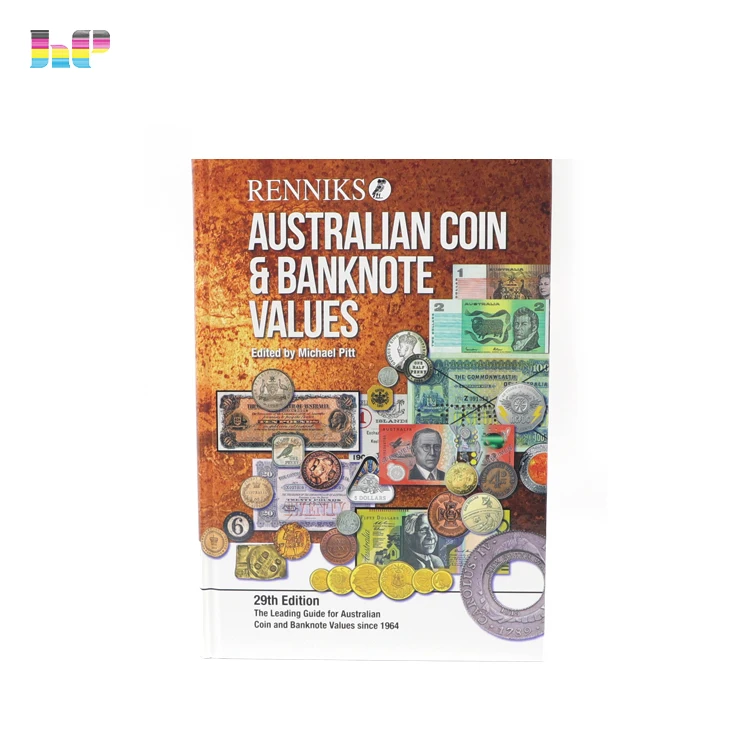

Best Other Packaging & Printing Services for Your Business Needs in 2025

In today's competitive market, Other Packaging & Printing Services play a crucial role in enhancing product appeal and ensuring safe delivery. Whether you need custom packaging solutions or specialized printing services, finding the right supplier is essential. This guide will help you navigate the options and make the best choice for your business.

How to Find Reliable Other Packaging & Printing Services from China in 2025

China remains a leading hub for Other Packaging & Printing Services, offering cost-effective and high-quality solutions. To find reliable suppliers, start by researching on platforms like Alibaba, where you can compare reviews, certifications, and product offerings. Look for suppliers with verified trade assurances and a proven track record. Additionally, attending trade fairs such as the Canton Fair can provide direct access to top manufacturers.

What Buyers Should Know Before Buying Other Packaging & Printing Services from China

Before purchasing, consider factors like material quality, customization options, and lead times. Ensure the supplier complies with international standards, such as ISO certifications. Request samples to evaluate the product firsthand. Also, clarify payment terms and shipping logistics to avoid unexpected costs. Building a long-term relationship with a trusted supplier can lead to better pricing and service.

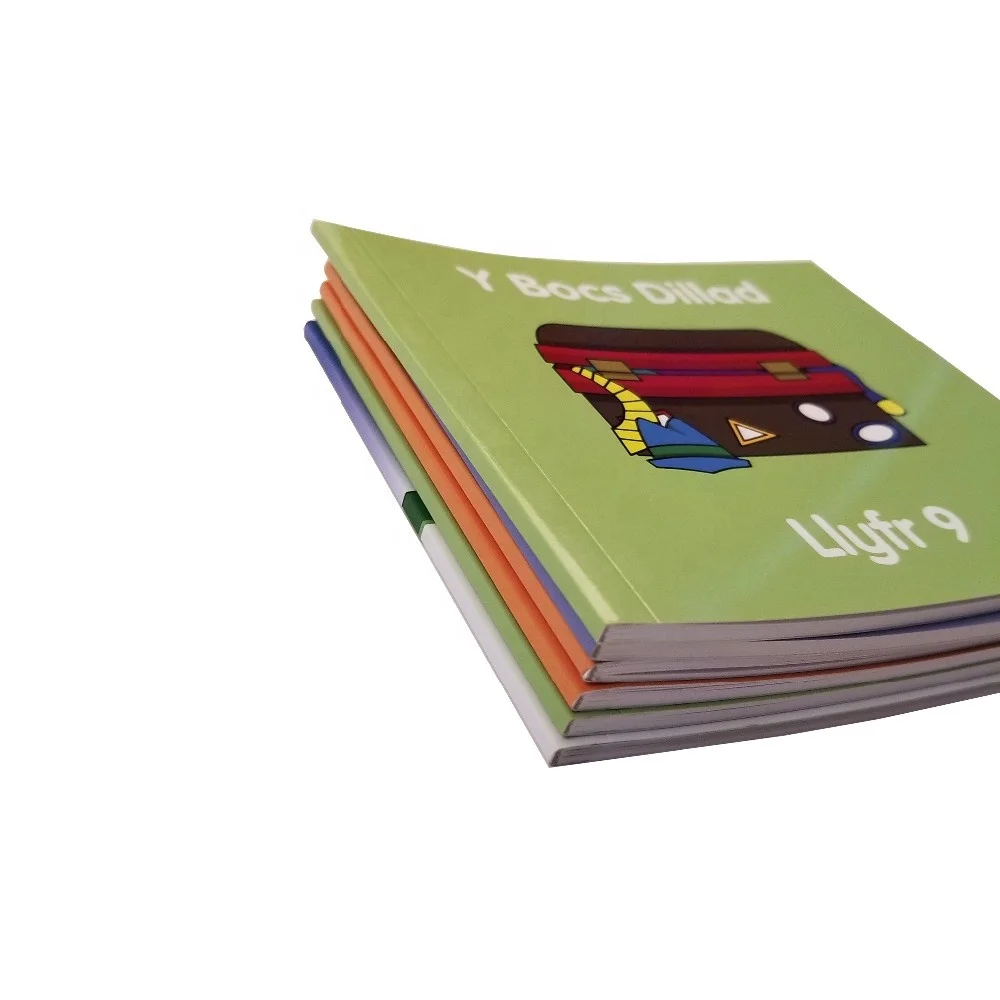

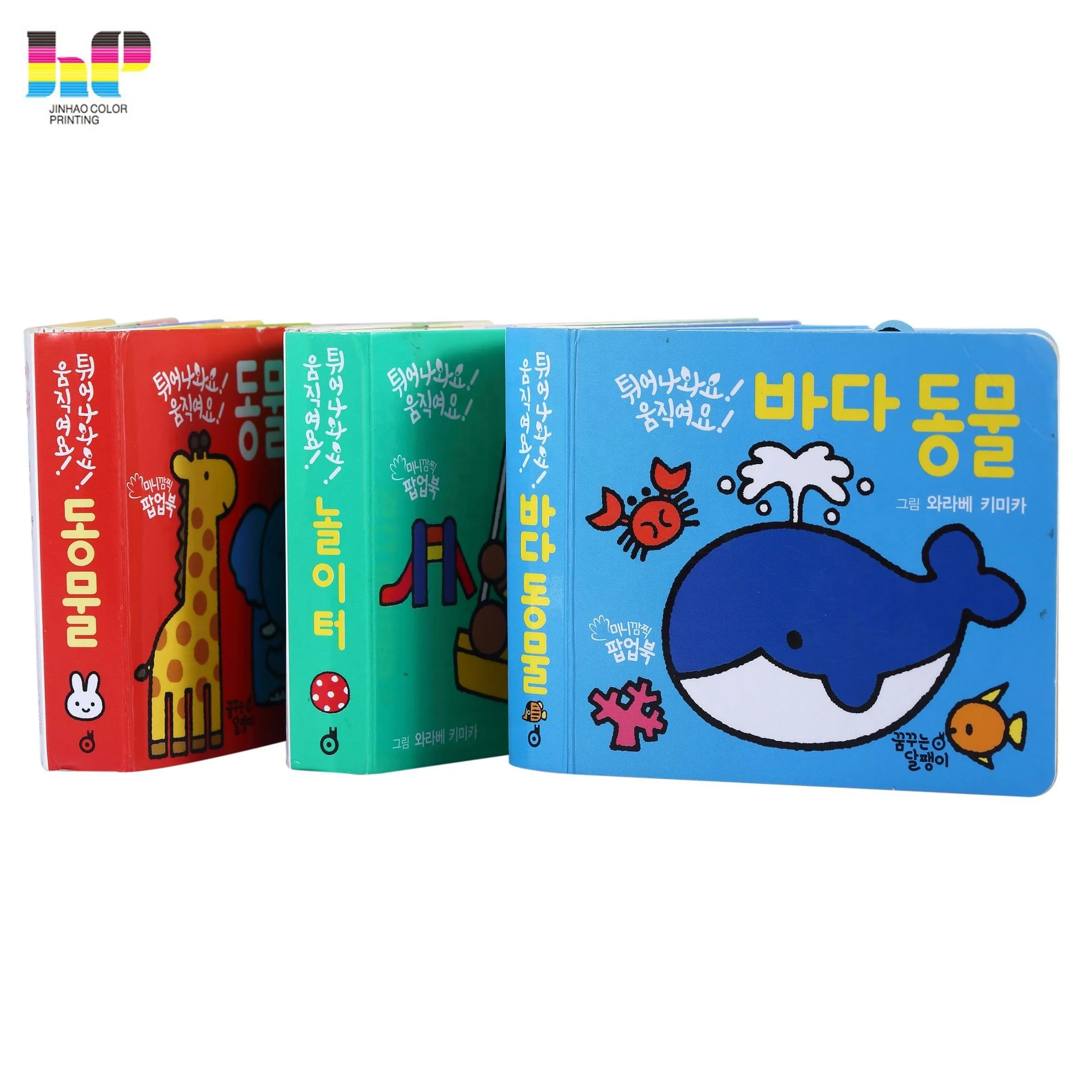

Types of Other Packaging & Printing Services

Other Packaging & Printing Services encompass a wide range of solutions, including:

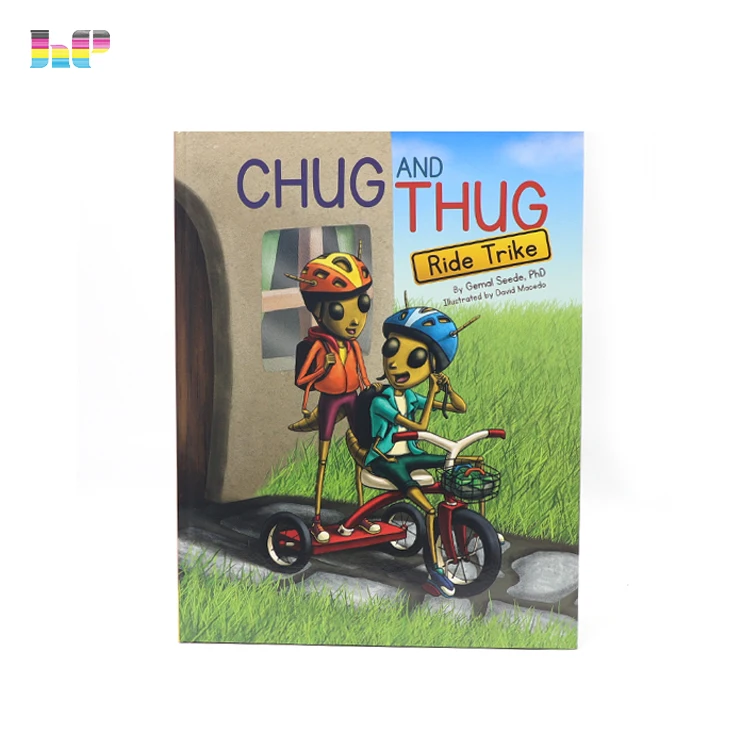

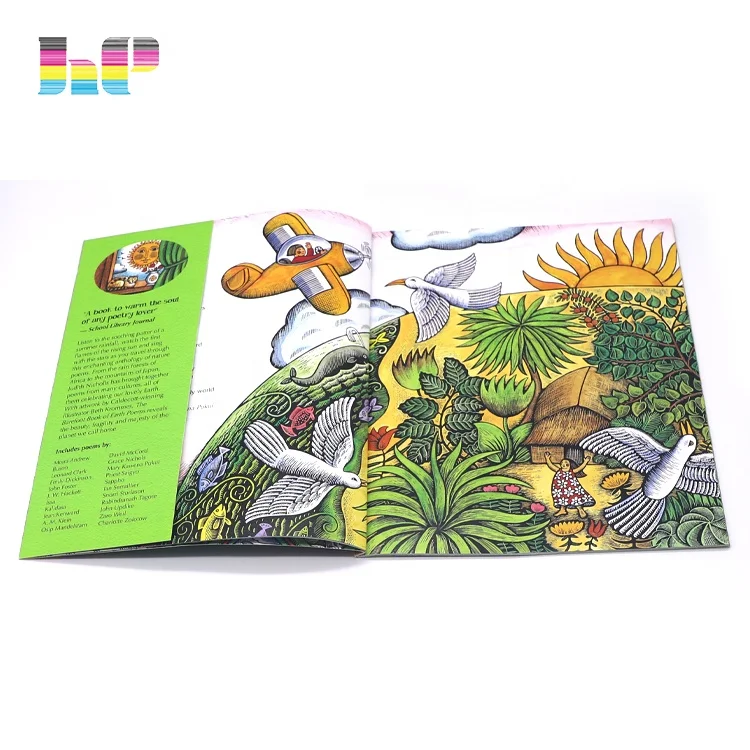

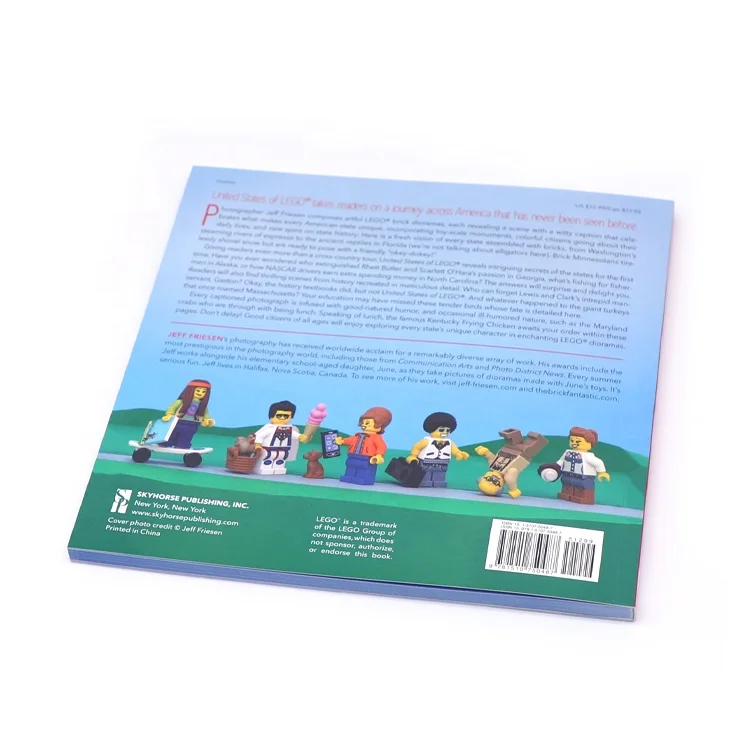

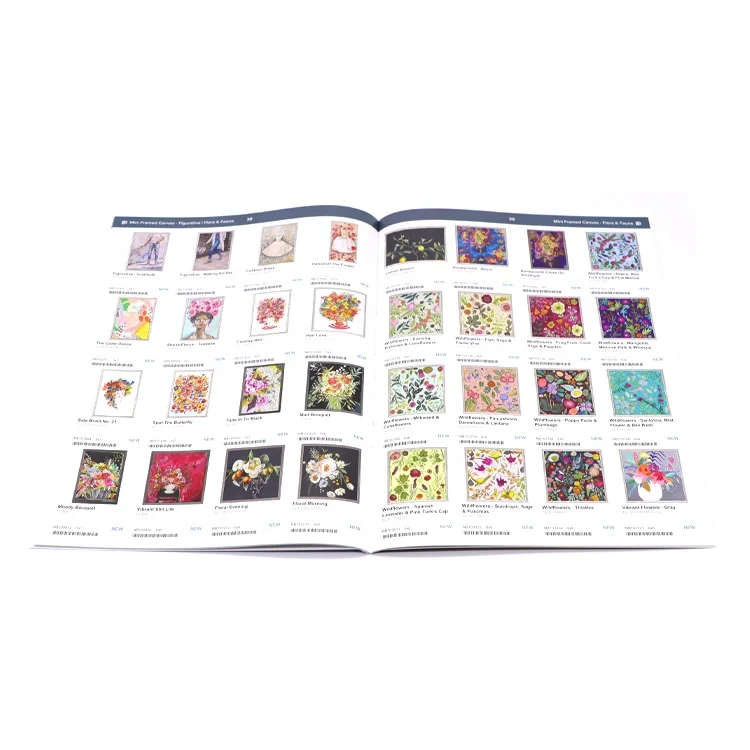

- Custom Box Printing

- Flexible Packaging

- Label and Sticker Printing

- Corrugated Packaging

- Promotional Packaging

Each type serves different business needs, from retail packaging to industrial applications.

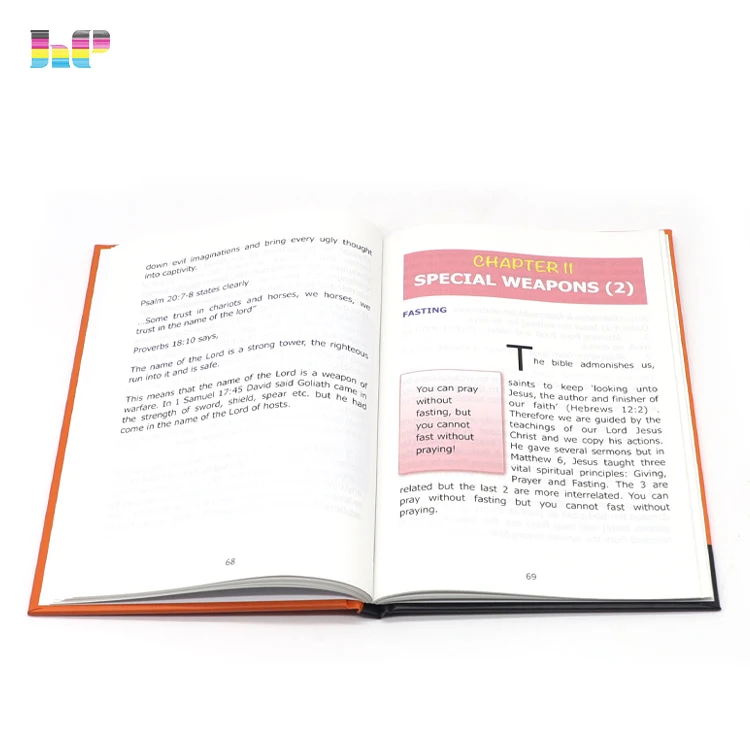

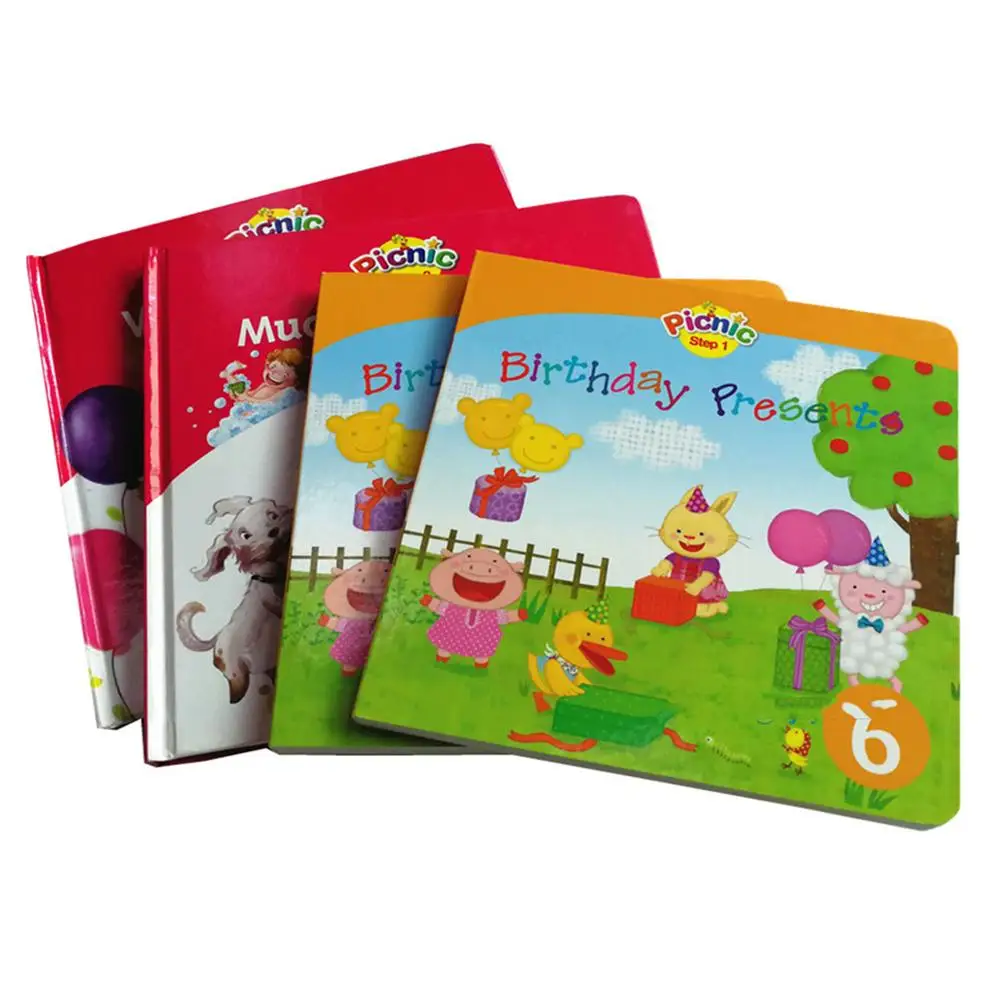

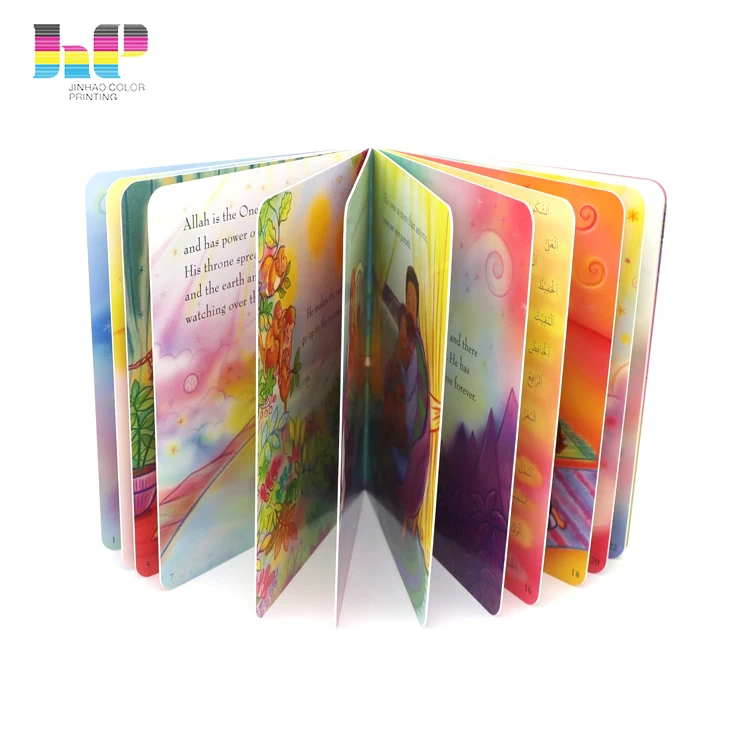

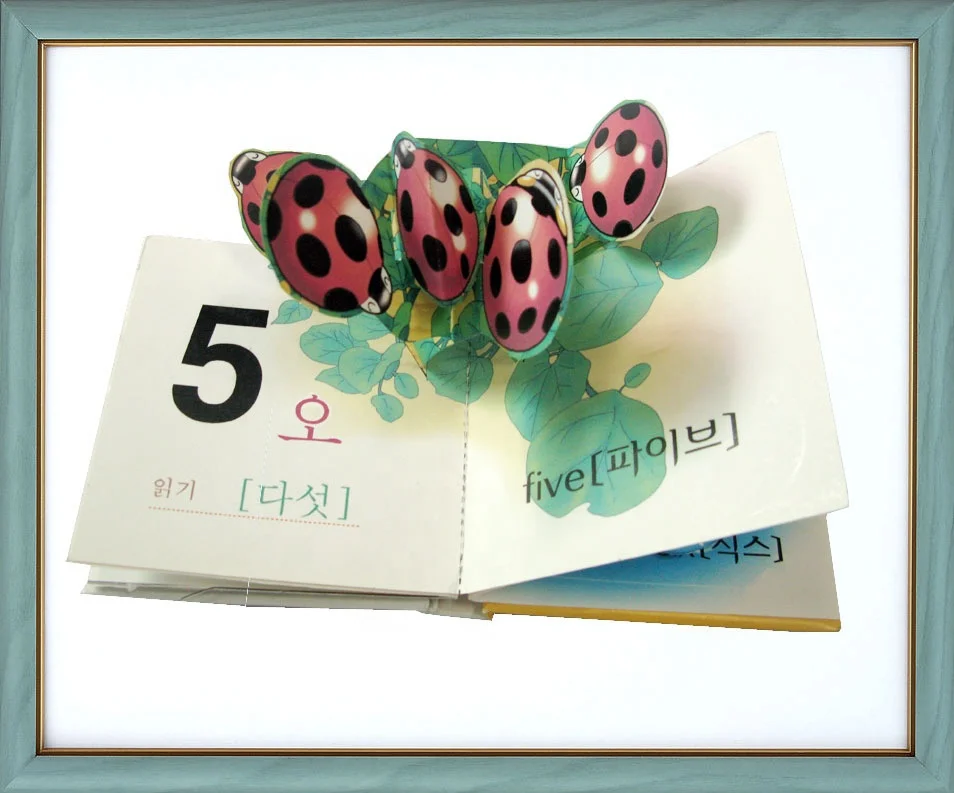

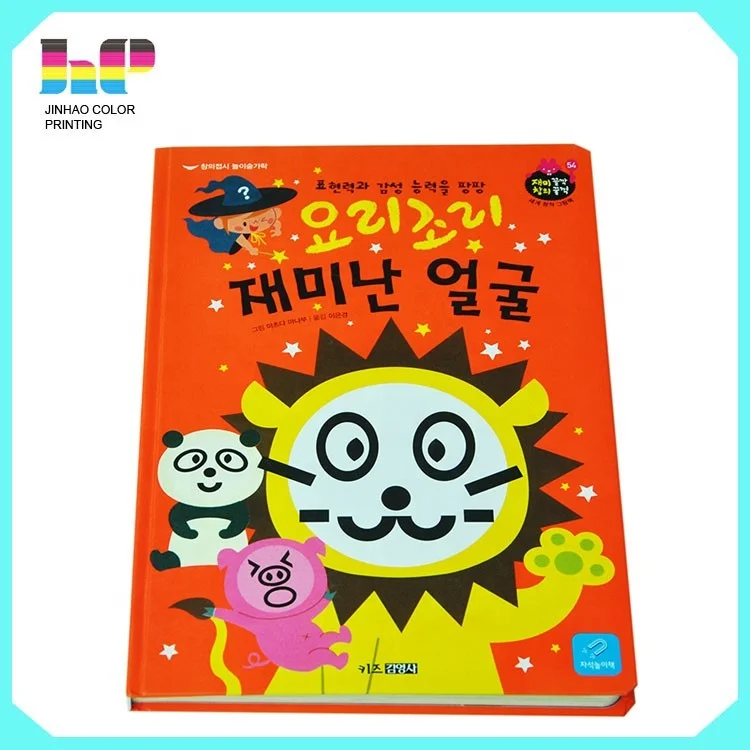

Functions and Features of Other Packaging & Printing Services

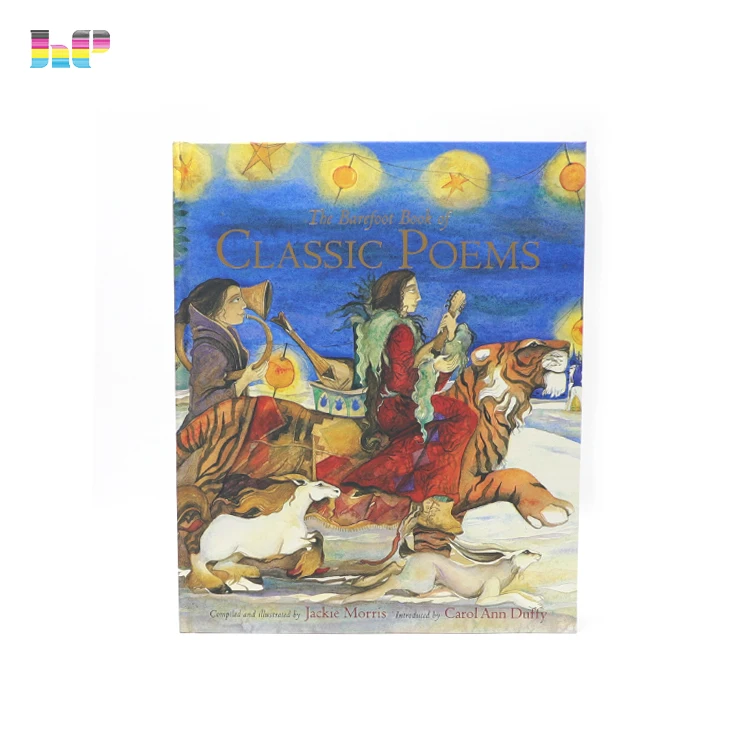

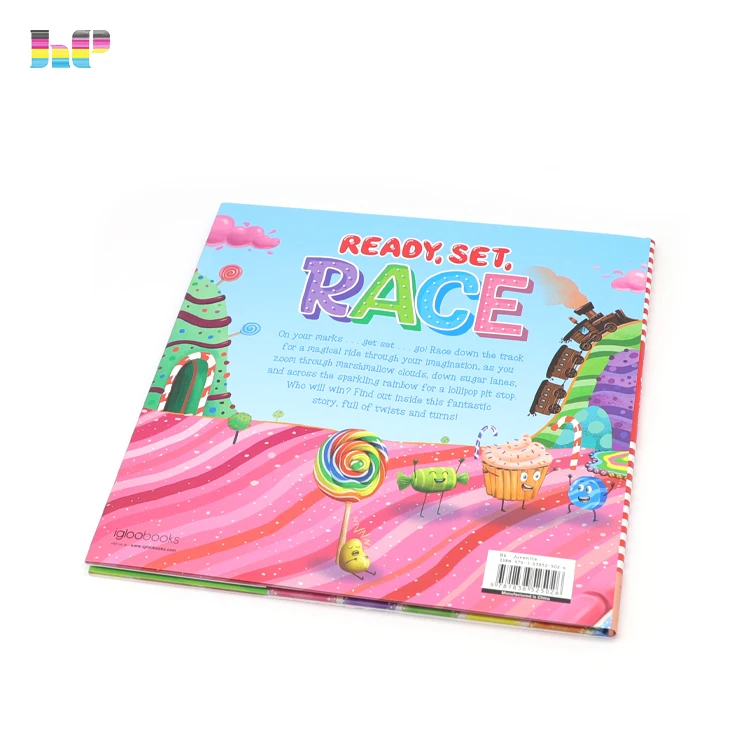

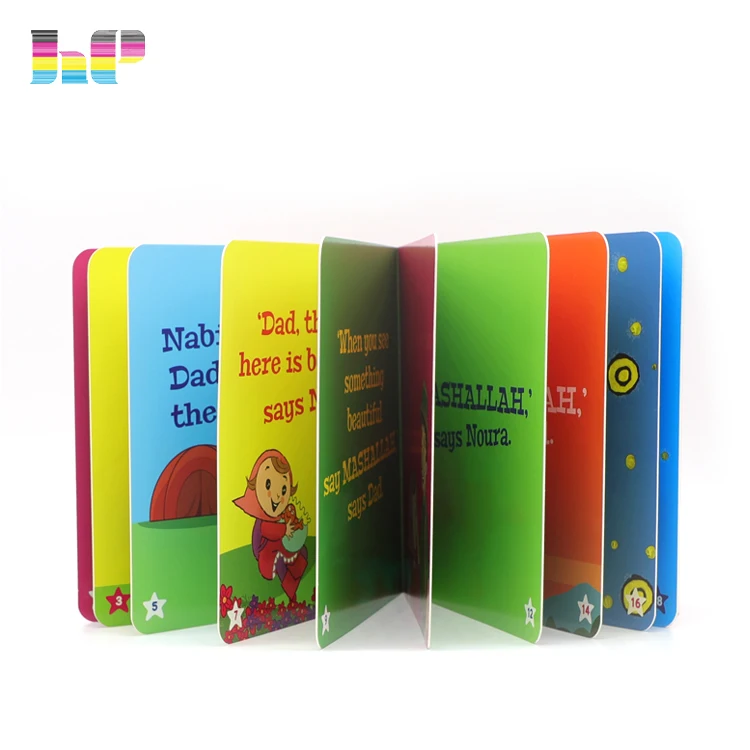

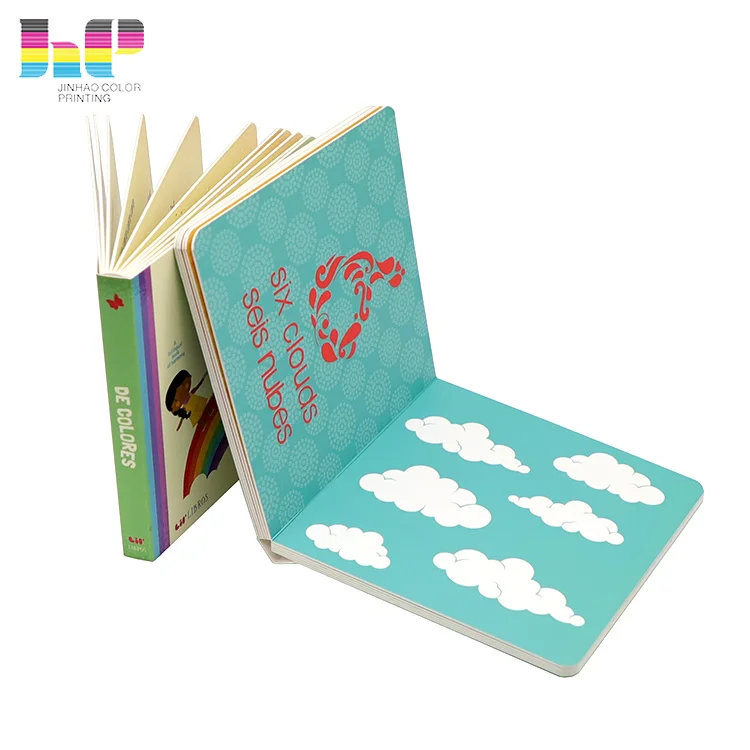

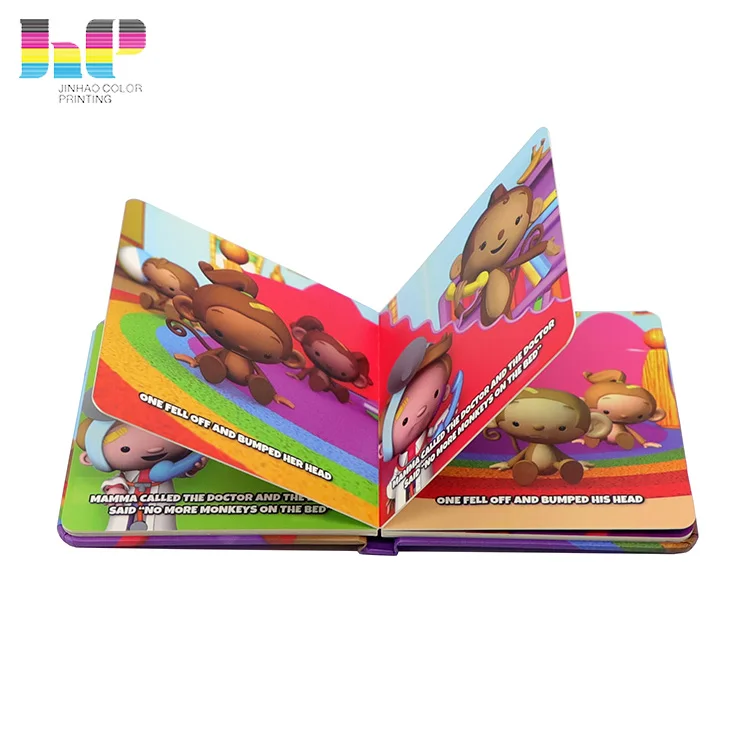

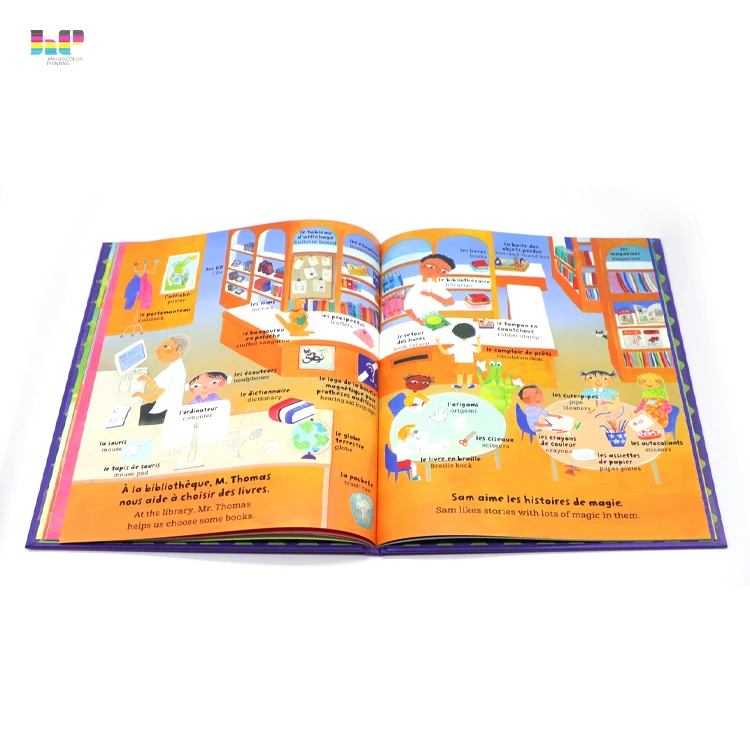

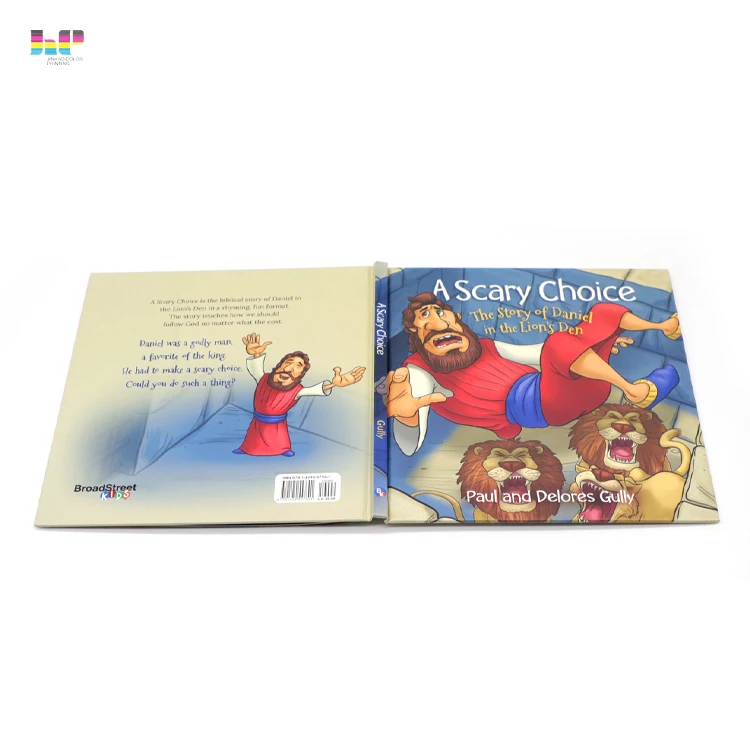

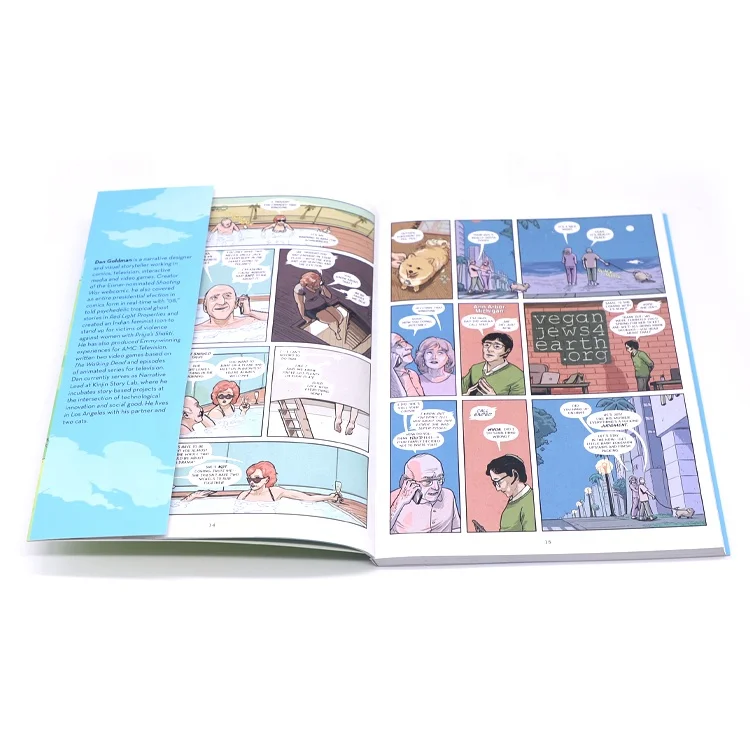

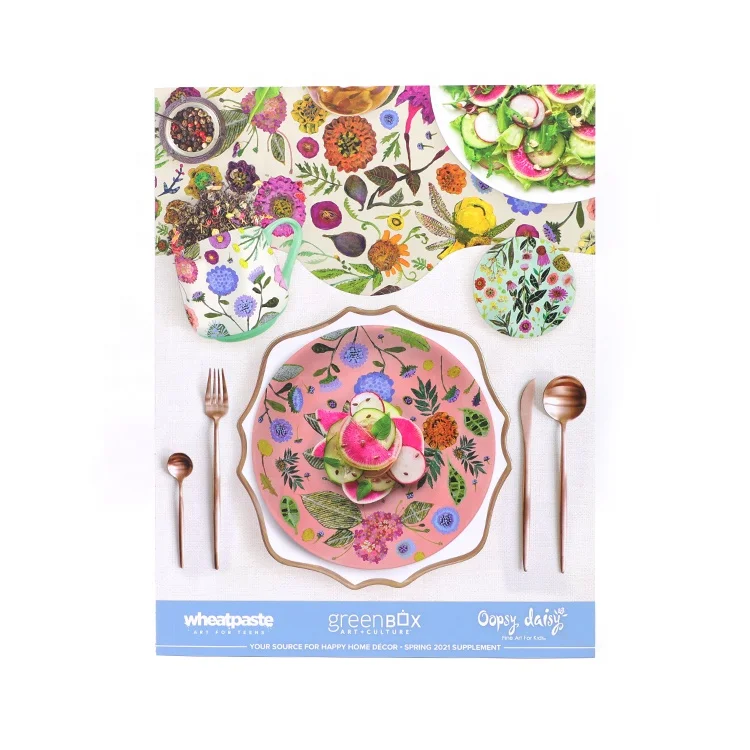

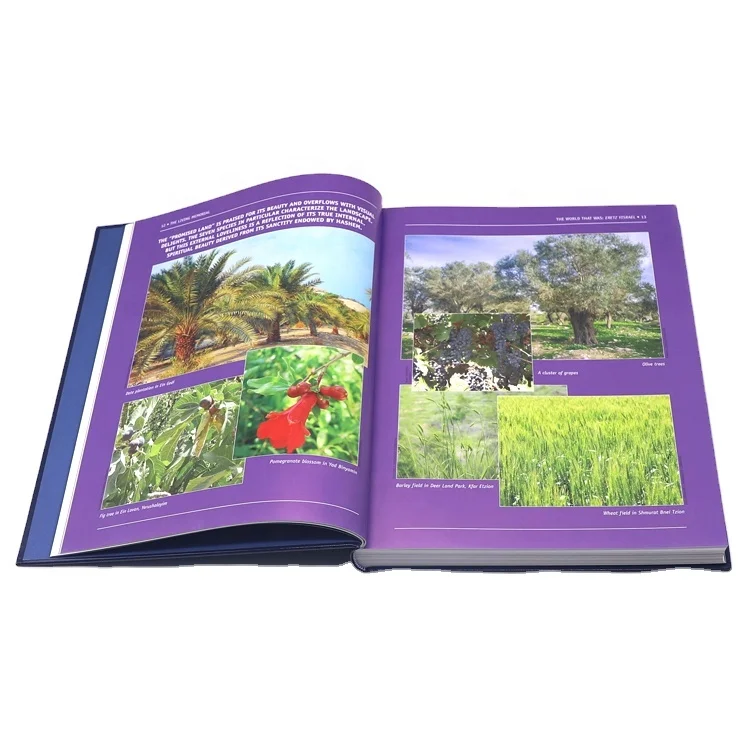

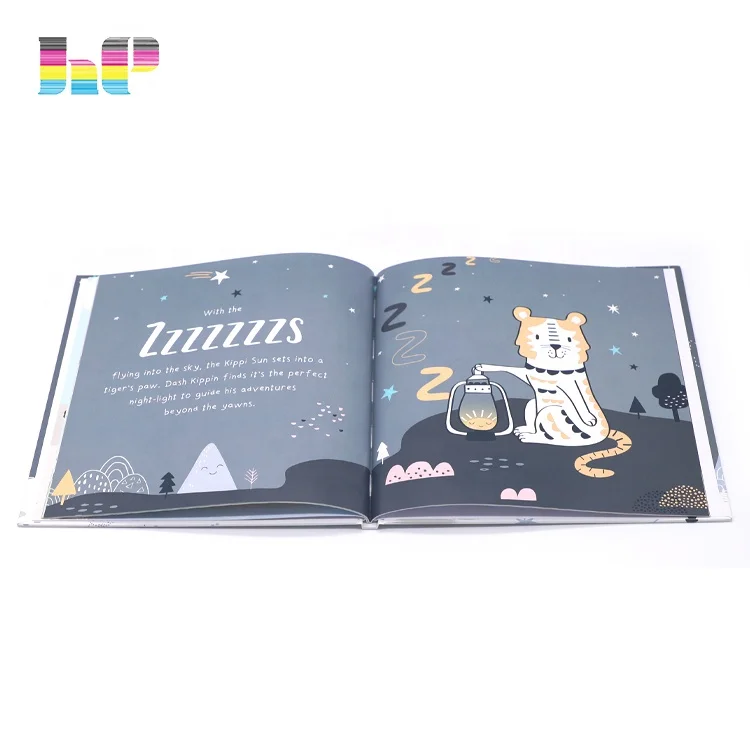

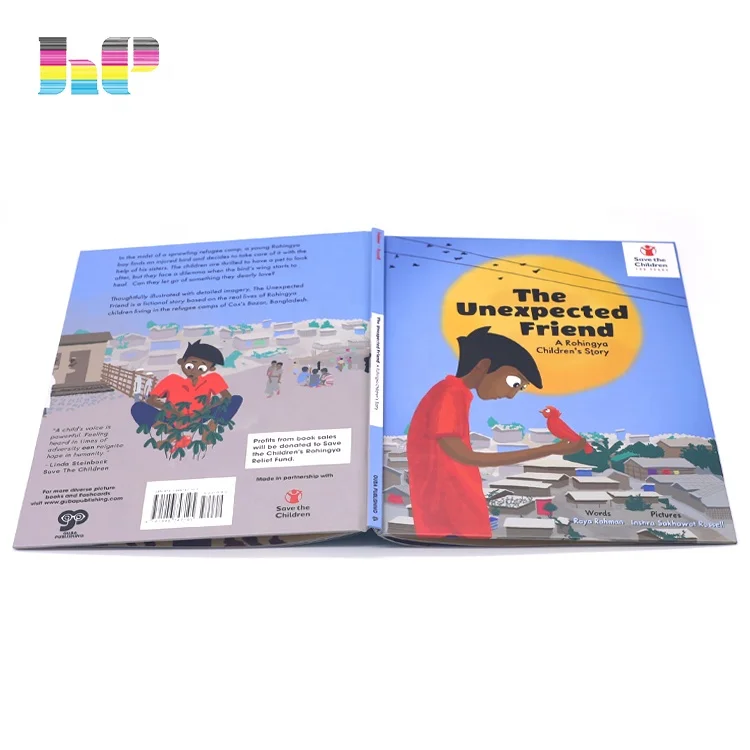

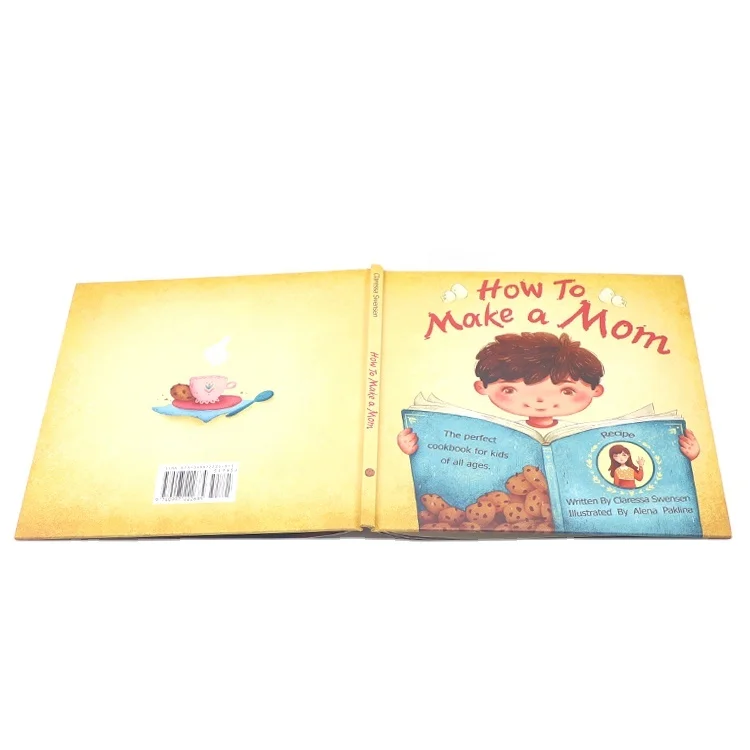

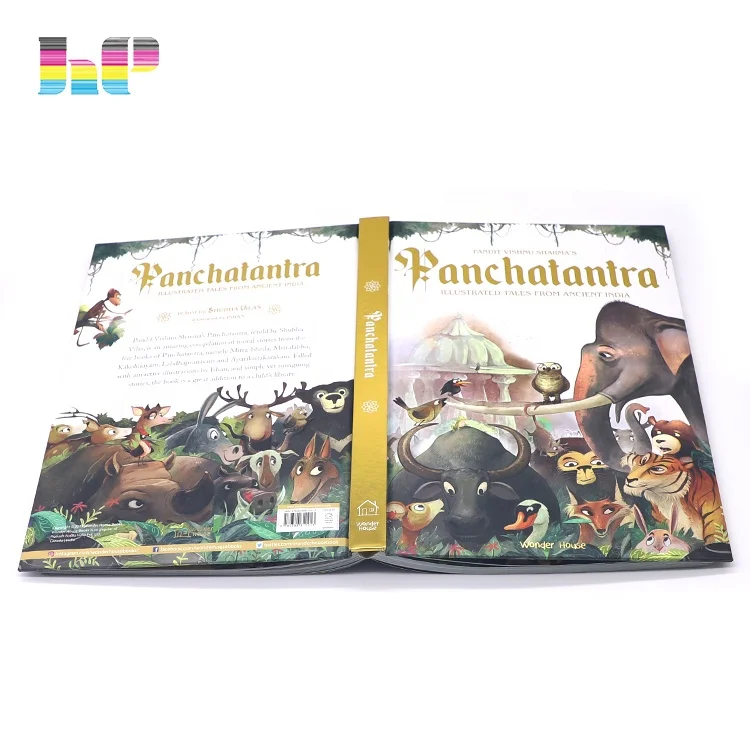

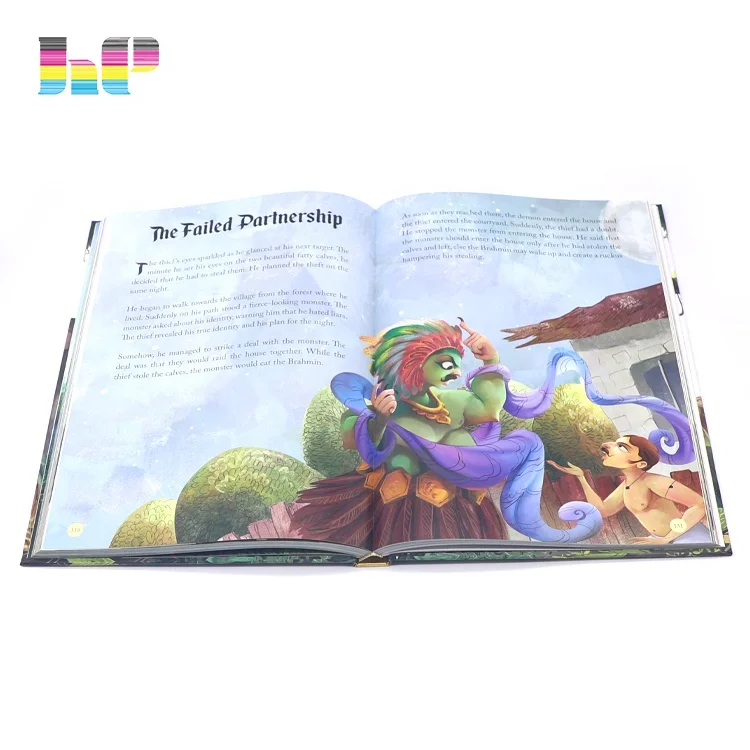

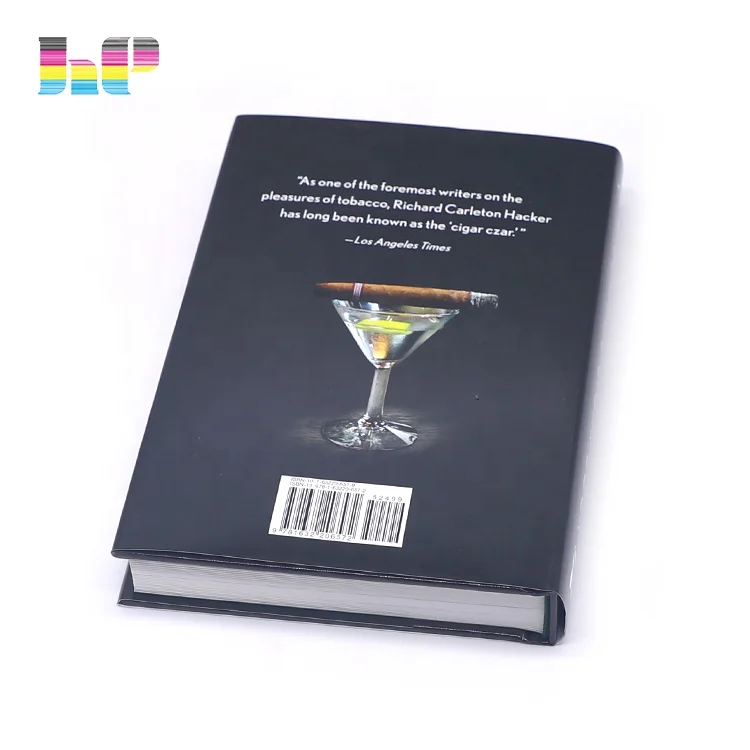

These services offer features like high-resolution printing, eco-friendly materials, and durable designs. Advanced options include UV coating, embossing, and holographic effects. The primary function is to protect products while enhancing brand visibility. For example, custom-printed boxes can significantly boost unboxing experiences and customer satisfaction.

Scenarios of Other Packaging & Printing Services

Other Packaging & Printing Services are used across various industries:

- E-commerce: Custom mailer boxes for online stores

- Food & Beverage: Safe and attractive food packaging

- Cosmetics: Luxury packaging for beauty products

- Electronics: Protective packaging for fragile items

How to Choose Other Packaging & Printing Services

Selecting the right service depends on your specific needs. Consider the following:

- Budget: Compare quotes from multiple suppliers

- Quality: Check material durability and print clarity

- Customization: Ensure the supplier can meet your design requirements

- Turnaround Time: Confirm production and delivery schedules

Other Packaging & Printing Services Q & A

Q: What is the minimum order quantity (MOQ) for custom packaging?

A: MOQs vary by supplier but typically start at 500-1000 units for custom orders.

Q: Are eco-friendly packaging options available?

A: Yes, many suppliers offer biodegradable and recyclable materials.

Q: How long does production take?

A: Production usually takes 2-4 weeks, depending on complexity and order size.

Q: Can I get samples before placing a bulk order?

A: Most suppliers provide samples for a fee, which is often credited toward your bulk order.

Q: What file formats are required for custom printing?

A: Vector files (AI, EPS) or high-resolution PDFs are preferred for best results.