Best Pumps for Your Needs: Types, Features, and Buying Guide

When it comes to moving fluids efficiently, pumps are indispensable tools in industries, agriculture, and even households. Whether you need to transport water, chemicals, or oils, selecting the right pump can make all the difference. This guide covers everything you need to know about pumps, from types and features to buying tips and FAQs.

How to Find Reliable Pumps from China in 2025

China remains a leading manufacturer of high-quality pumps, offering competitive prices and advanced technology. To find reliable suppliers, consider platforms like Alibaba, which vet manufacturers rigorously. Look for suppliers with certifications like ISO 9001 and positive customer reviews. Request samples to test performance before bulk orders.

What Buyers Should Know Before Buying Pumps from China

Before purchasing pumps from China, verify the supplier’s reputation, production capacity, and after-sales service. Ensure the product meets international standards like CE or UL. Negotiate shipping terms and warranty policies upfront to avoid hidden costs.

Types of Pumps

There are several types of pumps, each suited for specific applications:

- Centrifugal Pumps: Ideal for water supply and irrigation.

- Diaphragm Pumps: Perfect for handling corrosive or viscous fluids.

- Submersible Pumps: Used in drainage and sewage systems.

- Gear Pumps: Common in hydraulic systems and fuel transfer.

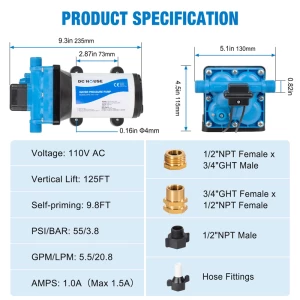

Functions and Features of Pumps

Modern pumps come with features like energy efficiency, corrosion resistance, and smart controls. Key functions include flow rate adjustment, self-priming, and overload protection. Always check the pump’s material (e.g., stainless steel for durability) and motor power for optimal performance.

Scenarios of Pumps

Pumps are used in diverse scenarios:

- Agriculture: Irrigation and pesticide spraying.

- Construction: Dewatering and concrete pumping.

- Household: Water supply and HVAC systems.

- Industry: Chemical processing and oil refineries.

How to Choose Pumps

Selecting the right pump involves evaluating:

- Fluid Type: Match the pump to the fluid’s viscosity and corrosiveness.

- Flow Rate: Ensure the pump meets your volume requirements.

- Head Pressure: Check the maximum height the pump can lift fluid.

- Energy Efficiency: Opt for models with low power consumption.

Pumps Q & A

Q: What’s the lifespan of a typical pump?

A: Depending on usage and maintenance, most pumps last 5–10 years.

Q: How do I maintain my pump?

A: Regularly clean filters, check seals, and lubricate moving parts.

Q: Can I use one pump for different fluids?

A: Only if the pump is designed for multi-fluid use; otherwise, it may corrode or clog.

Q: What’s the difference between centrifugal and diaphragm pumps?

A: Centrifugal pumps are better for high-flow applications, while diaphragm pumps handle viscous or hazardous fluids.

Q: Are Chinese pumps reliable?

A: Yes, many Chinese manufacturers produce high-quality pumps that meet global standards.